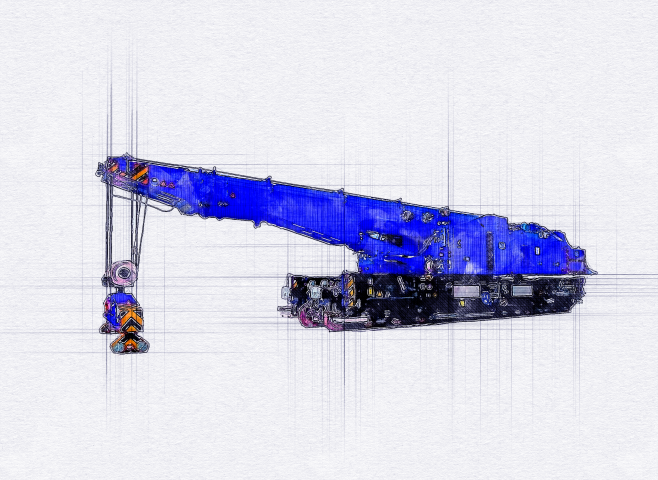

– Railway Crane

High Lifting Capacity:

Engineered to handle substantial loads with a lifting capacity of up to 172 tons, railway cranes are ideal for heavy-duty applications such as installing large track sections and infrastructure components.

Advanced Maneuverability:

The train crane’s advanced mobility feature allows it to navigate tight spaces and operate efficiently under overhead electric lines, ensuring precise placement of materials and components.

– Switch Tilter

Mobility and Adaptability:

The switch tilter is designed for easy transportation and setup, allowing it to be quickly deployed. Its compatibility with different railway cranes and vehicles ensures ensures flexibility and safety for diverse project needs.

Robust Construction:

Built with high-strength materials and designed to withstand harsh working conditions, the switch tilter can handle substantial loads and is suitable for demanding railway applications.

– Switch Tilter

Mobility and Adaptability:

The switch tilter is designed for easy transportation and setup, allowing it to be quickly deployed. Its compatibility with different railway cranes and vehicles ensures ensures flexibility for diverse project needs.

Robust Construction:

Built with high-strength materials and designed to withstand harsh working conditions, the switch tilter can handle substantial loads and is suitable for demanding railway applications.

– Why choose our cranes?

Exclusive Distributor for The America’s of Telescopic Railway Cranes

Our cranes are suitable for:

- Railway underpasses

- Railway bridges

- Substations

- Trackside railway structures

40 Years of expertise

At Railquip we have built expertise on the design, supply, installation and service & maintenance of heavy-duty railroad maintenance equipment across North America.

Designed to Fit the Purpose

Any technical data can be modified at the design stage if the progress allows for the requested modifications.

Can be equipped to operate in super elevated curves under full capacity.

Stability & Safety Features

The cranes can be equipped with advanced stability and safety features to keep the crane’s center of gravity point and ensure the protection of both personnel and machinery.

Preventive Maintenance - Troubleshooting & Repair

We offer turnkey service and preventive maintenance. Our dedicated service team will collaborate with yours to keep your operations running smoothly, preventing downtimes and unexpected issues.

– FAQ’S

How are railway cranes powered?

Railway cranes can be powered by various sources, including diesel engines, electric motors, or a combination of both. The choice of power source depends on the specific requirements of the crane and the operational environment.

Can railway cranes operate on all types of rail tracks?

Railway cranes are designed to operate on standard gauge rail tracks, which are the most common type of tracks worldwide. However, specialized railway cranes can be configured to operate on narrow gauge or broad gauge tracks, depending on the specific rail network requirements.

What is the lifting capacity of railway cranes?

The lifting capacity of railway cranes varies depending on their size and configuration. Smaller railway cranes can have a lifting capacity of a few tons, while larger ones can lift loads weighing over 100 tons or more.

How are railway cranes maintained?

Regular maintenance and inspections are essential to ensure the safe and efficient operation of railway cranes. Maintenance activities include lubrication of moving parts, inspection of hydraulic systems, and testing of safety features. These tasks are typically performed by trained technicians following manufacturer guidelines.

What are the safety precautions when operating a railway crane?

When operating a railway crane, it is essential to follow strict safety protocols. This includes proper training for operators, adherence to load capacity limits, regular equipment inspections, and compliance with all relevant safety regulations. Additionally, proper communication and coordination with other personnel involved in the lifting operation are crucial to ensure overall safety.

– Other Products