Use a railcar mover is crucial for efficient, precise, and safe transportation of railcars within rail yards. Understanding the different types available and their specific functionalities can significantly enhance your operational efficiency.

Assessing your needs: which railcar mover is right for you?

Choosing the right railcar mover is a strategic decision that hinges on a deep understanding of your specific operational needs and environmental factors. Here’s how to assess which mover is best suited for your operations:

Operational Environment:

- Industrial Areas: If your operations are based in industrial areas with high traffic and frequent loading activities, consider railcar movers that are robust and designed for heavy-duty use. These areas often require equipment that can withstand rigorous conditions and constant use.

- Logistics Hubs: For more dynamic environments like logistics hubs, where railcars need to be moved between various types of infrastructure (e.g., from rails to roads), versatility is key. A railcar mover that can easily transition between different terrains while handling various cargo types would be ideal.

Load Requirements:

- Heavy Loads: For operations that regularly deal with heavy or oversized loads, a railcar mover with a high power output and enhanced towing capabilities is necessary. Shunters, for example, are typically designed to manage heavy weights, making them suitable for industries such as manufacturing or mining.

- Diverse Cargo: In settings where cargo types vary widely—from containers to bulk commodities—a flexible railcar mover with adjustable settings and capabilities can help manage different load requirements efficiently.

Safety Concerns:

- Hazardous Materials: Facilities handling hazardous materials must prioritize safety and precision. Railcar movers, which offer advanced control systems and precise handling, reduce the risk of accidents and ensure safe operation in potentially dangerous environments.

- Precision Handling: Operations requiring high precision, such as in chemical plants or delicate cargo handling, need railcar movers equipped with sophisticated navigation and positioning technologies to avoid operational mishaps.

Contextual Considerations:

- Space Constraints: Evaluate the spatial limitations of your rail yard. Compact models with good maneuverability are essential in tight spaces to prevent logjams and ensure smooth operations.

- Frequency of Use: Consider how often the railcar mover will be used. High-frequency environments demand durable and reliable machines that can operate continuously without significant downtime for maintenance.

- Budget and Maintenance: Your budget will influence your choice. More sophisticated models with advanced features might offer long-term savings through efficiency and durability but come at a higher initial cost. Additionally, consider the maintenance requirements and the availability of spare parts and service.

Battery-powered railcar movers

Battery-powered railcar movers are becoming increasingly popular due to their emission-free operation, making them ideal for indoor and environmentally sensitive operations. These movers are equipped with electric drives that not only reduce carbon footprints but also lower operational costs by eliminating the need for diesel fuel:

- Emission-Free Operation: Perfect for workshops and indoor applications where air quality is a concern.

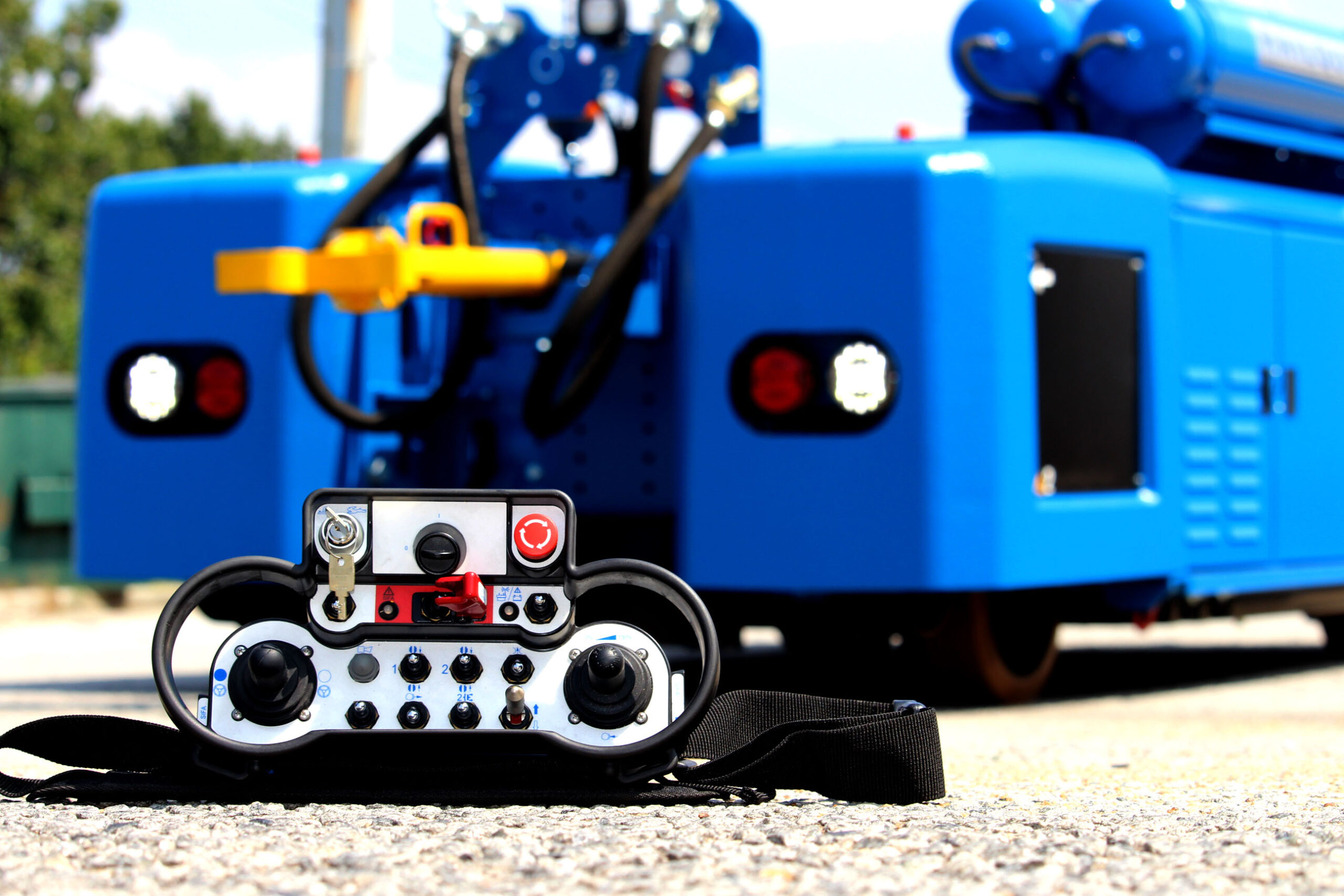

- Patented Rail Guidance Equipment: Allows for easy and quick on and off-tracking, enhancing operational flexibility.

These are ideal for companies looking to enhance their environmental stewardship while maintaining efficient rail yard operations. These units are especially beneficial in urban rail settings where noise and pollution regulations are stringent.

Maxi rail car mover LPG/Gas

The Maxi Rail Car Mover is known for its maneuverability and cost-effectiveness. Offering multi-directional capabilities, this mover transforms rail yard operations by providing a versatile solution that adapts to various tasks:

- LPG/Gas Powered: Offers a balance between environmental considerations and power needs.

- Cost-Effective Operations: Reduces the need for large, more expensive shunting locomotives.

This railcar mover is suited for rail transit maintenance shops where space and budget constraints are prevalent. Its versatility makes it an excellent choice for rail yards that require frequent repositioning of railcars.

Forklift truck propelled mover

An economical solution for moving railcars, the Forklift Truck Propelled Mover leverages existing forklift assets to move railcars, thereby reducing the need for specialized shunting vehicles that comes with:

- Adaptable Speed Options: Comes with a conversion kit to adjust speeds, suitable for different operational paces.

- Low Maintenance: Due to its solid construction, it requires minimal upkeep, ensuring more time is spent on operations than on repairs.

Perfect for small to medium-sized rail operations that require a cost-effective solution for moving railcars. It’s particularly useful in industries like agriculture or manufacturing, where flexibility in railcar movement is essential but large investments in specialized equipment are not feasible.

Real-world application: transforming BNSF’s rail operations

Discover the transformative impact of our advanced railcar movers through a detailed case study on BNSF Railway. Our technology played a crucial role in revolutionizing their maintenance operations by enhancing safety and reducing environmental impact. For an in-depth look at this successful implementation, read our detailed case study on the BNSF project.

For BNSF, we customized a railcar mover to efficiently handle the weight and dimensions of their trains within the constraints of their maintenance workshops. The introduction of our railcar mover at BNSF led to more efficient maintenance workflows, a safer working environment for employees, and a significant decrease in carbon emissions.

Conclusion:

Choosing the right railcar mover can significantly impact the efficiency and environmental footprint of your rail operations. From battery-powered options that offer clean energy solutions to versatile gas-powered and forklift-propelled models, each type of mover has specific features that cater to different operational needs.

Enhance your rail yard operations with our advanced railcar movers. Reach out today to learn more about our offerings and how they can be integrated into your operations for improved efficiency and sustainability.