Case Study

Overview

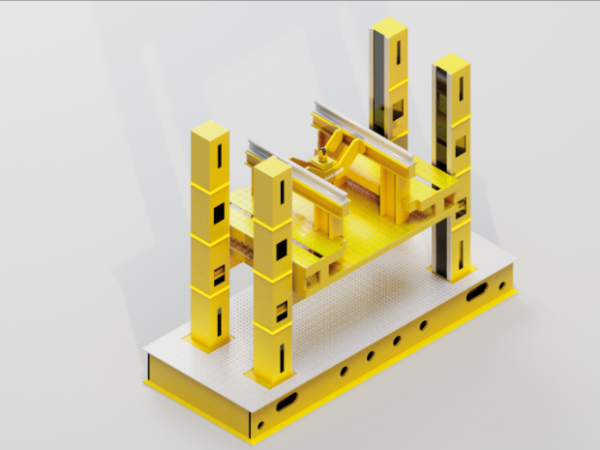

WMATA needed to replace its stationary drop table at the Shady Grove S&I shop due to excessive maintenance costs and aging parts. Railquip provided a custom-designed solution that was more cost-effective than a rebuild and was installed in a shorter time frame, incorporating new safety features to improve operational efficiency.

– Our Process

– The Results

The new equipment provided by Railquip was less expensive than rebuilding the original system, and it was installed in a shorter time frame. Enhanced safety features and self-monitoring systems were added, increasing employee safety and reducing operational downtime

Key Specifications:

System: Drop table and manually operated turntable

Location: Shady Grove S&I Shop, WMATA

Function: Lifts and lowers locomotive bogies between the main floor and basement for repairs and storage.

New features: Advanced safety, automated monitoring, and a custom design to fit the existing pit.

“I had the pleasure of working with Railquip’s team on a new drop table for DC’s Metro system. This equipment was new according to the historical specifications and resulted in a comprehensive and advanced solution that supported the owner’s needs for increased, open competition. Railquip’s leadership, both at HQ and on the project, provided exceptional responsiveness to our requirements, helping the owner deploy the new drop table and developing a new contractor and supplier for future needs.”— Jeffrey Mertens, Project Manager

Washington Metropolitan Transit Authority

ABOUT THE PRODUCT

The product used in this project included a custom-designed drop table and manually operated turntable, tailored to fit the existing infrastructure at WMATA’s Shady Grove facility. These products were engineered to maximize operational efficiency, allow smooth movement of bogies between floors, and meet rigorous safety standards.

The Benefits of a Drop Turntable

- Cost-effective: The custom solution was more affordable than rebuilding the original system.

- Faster Installation: The new equipment was installed in a shorter period compared to the rebuild.

- Enhanced Safety:Advanced safety features and monitoring systems were added to protect employees and minimize downtime.

- Custom Design:The new equipment was designed to fit into the existing pit, avoiding major modifications to the existing infrastructure.

–More Case Studies

CERREJÓN COAL MINE IN COLOMBIA Case Study

To modernize Cerrejón’s lifting capabilities, Railquip and Eymaq provided a tailored solution: three sets of four 60-ton lifting jacks designed to replace outdated equipment

Washington Metropolitan Area Transit Authority – Case study

WMATA needed to replace its stationary drop table at the Shady Grove S&I shop due to excessive maintenance costs and aging parts. Railquip provided

Bay Area Rapid Transit Authority (BART) Case Study

BART required a solution to efficiently change the direction of railcars in their existing railyard. Railquip’s Automated Railcar Turntable provided a seamless, automated system

AMTRAK: Penn Station Rehabilitation Project Case Study

AMTRAK needed a custom-built Railbound Tunnel Crane for the New York Penn Station Rehabilitation Project. The crane had to operate within strict clearance limits

O-Train Case Study

In 2015, the O-Train in Ottawa, Canada, sought a complete train maintenance facility for their new fleet. Railquip provided a fully customized underground lifting

BNSF Burlington Northern Santa Fe Case Study

BNSF required a safer, more efficient way to pull locomotives over their wheel truing machine, addressing safety concerns and reducing pollution in the workshop.

Long Island Railroad Case Study

LIRR needed a safe and efficient solution for rerailing derailed trains due to frequent derailments that required costly external contractors. Railquip provided a standard

Clark Construction – Case study

In pursuit of operational excellence, our client sought to standardize maintenance practices across all locations with an established maintenance system featuring multiple turntables. The

TLC CASINO ENTERPRISES, INC.

Our task was to design, manufacture, and install a rotating bar floor in an existing 2nd-floor restaurant, taking into consideration the limitations imposed by