BART – BAY AREA RAPID TRANSIT AUTHORITY

Overview

In pursuit of operational excellence, our client sought to standardize maintenance practices across all locations. With an established maintenance system featuring multiple turntables. The challenge: A gap existed in an existing railyard where the directional change of railcar movers lacked a viable solution.

Solution

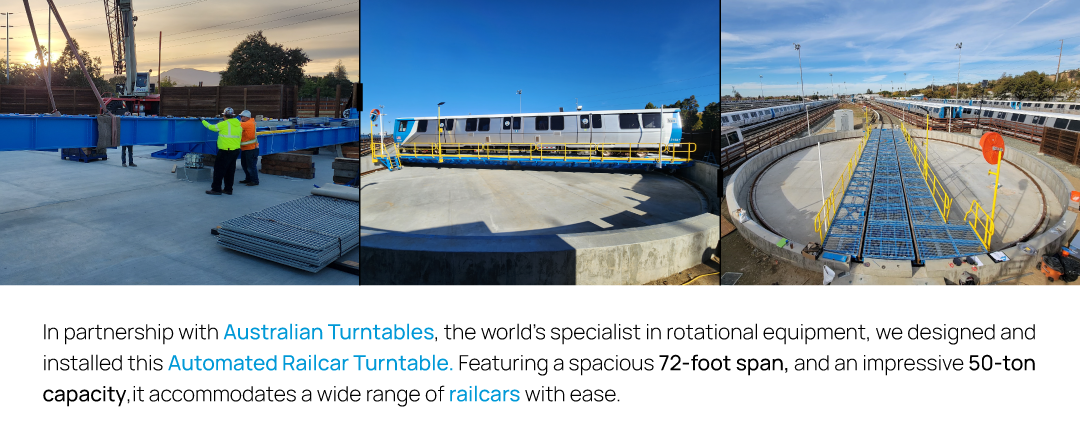

In collaboration with our esteemed partners at the Australian Turntable Company, we deployed our Automated Railcar Turntable for the Bay Area Rapid Transit (BART) in Concord, CA.

Our Process

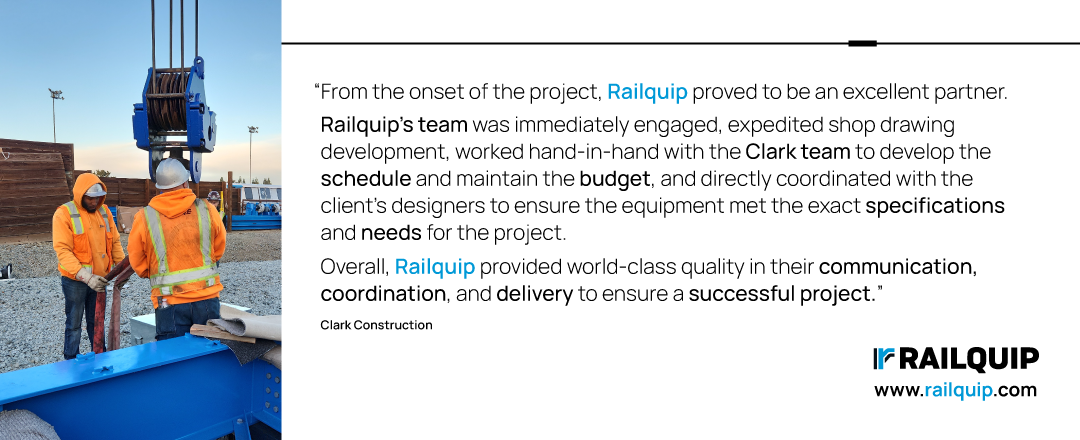

- Thorough Location and Turntable Specification Review

- Railquip (RQ) provided a comprehensive quotation for an Automated Railcar Turntable precisely tailored to meet the identified requirements. This solution was not only aligned with the client’s needs but was also engineered for ease of maintenance and incorporated readily available spare parts.

- We collaborated closely with the client’s engineering team. This collaborative effort was vital in confirming that the specifications aligned perfectly with the operational needs before moving forward with manufacturing.

- Upon receiving client approval, we swiftly engaged with our trusted Australian suppliers. We overview the manufacturing process, ensuring the turntable was crafted to the highest standards of quality and precision.

- Seamless Shipment and Installation

- Operator and Maintenance Training. Our commitment to client success extended beyond installation. We conducted comprehensive operator and maintenance training sessions, empowering the client’s team with the knowledge and skills needed to operate and maintain the turntable effectively.

The Results

Key Specifications:

- Span: Boasting a substantial 72-foot span, our turntable accommodates railcars with a robust 50-ton capacity.

- Automated Alignment: With advanced sensor technology, wheel chocks automatically extend into place when the railcar is centered, ensuring precise alignment.

- Effortless 180-Degree Spin: At the push of a button, the Turntable smoothly retracts the locking actuator, allowing the railcar to elegantly spin 180 degrees.

- Post-spin, the locking actuator extends, aligning the rails perfectly, while the retractable wheel chocks seamlessly disengage for the railcar’s release.

- Gravity-Assisted Departure: Built on a 1-degree slope, the turntable facilitates the railcar’s departure via gravity, ensuring a controlled descent as brakes are released.

Related Projects