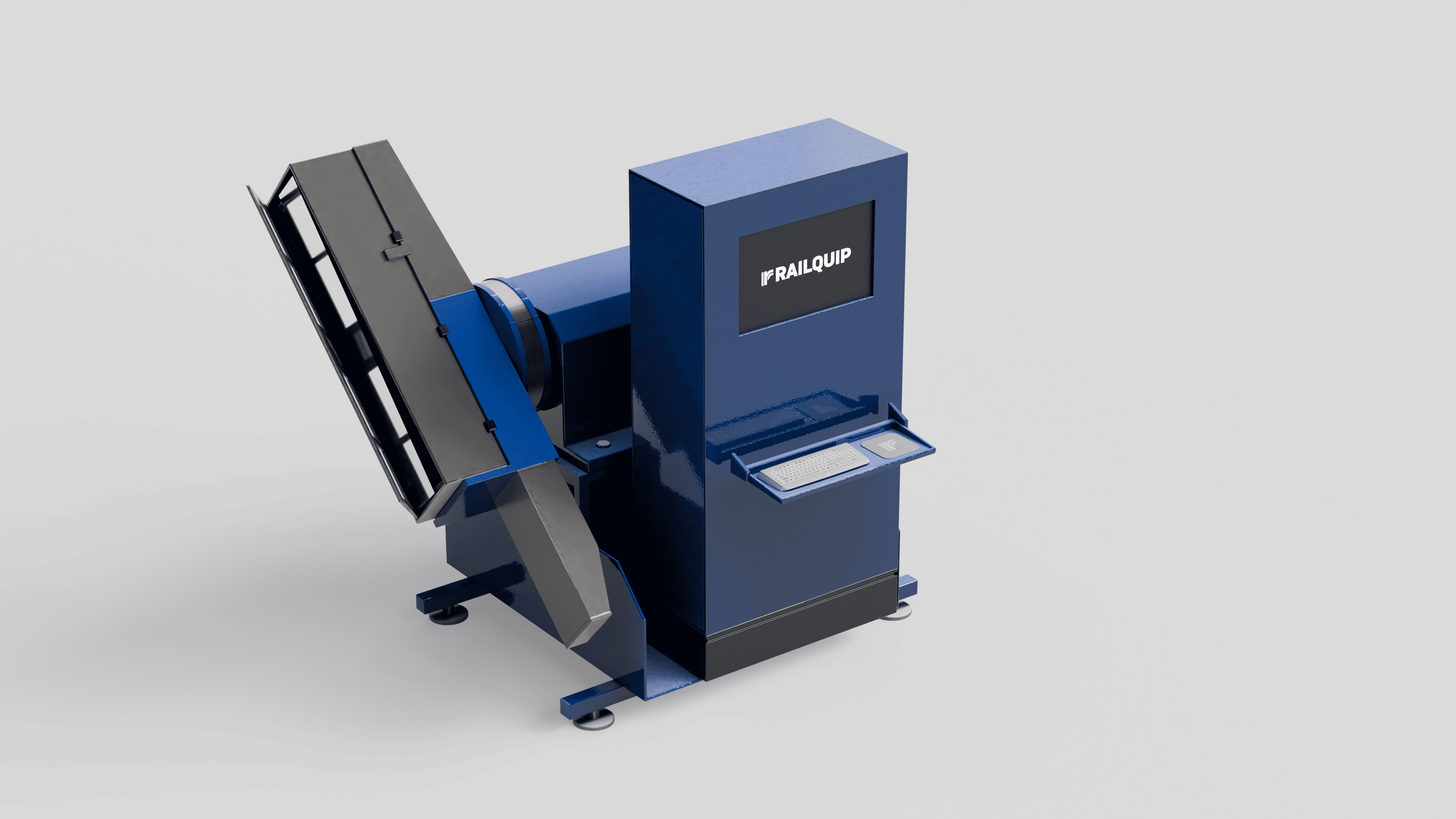

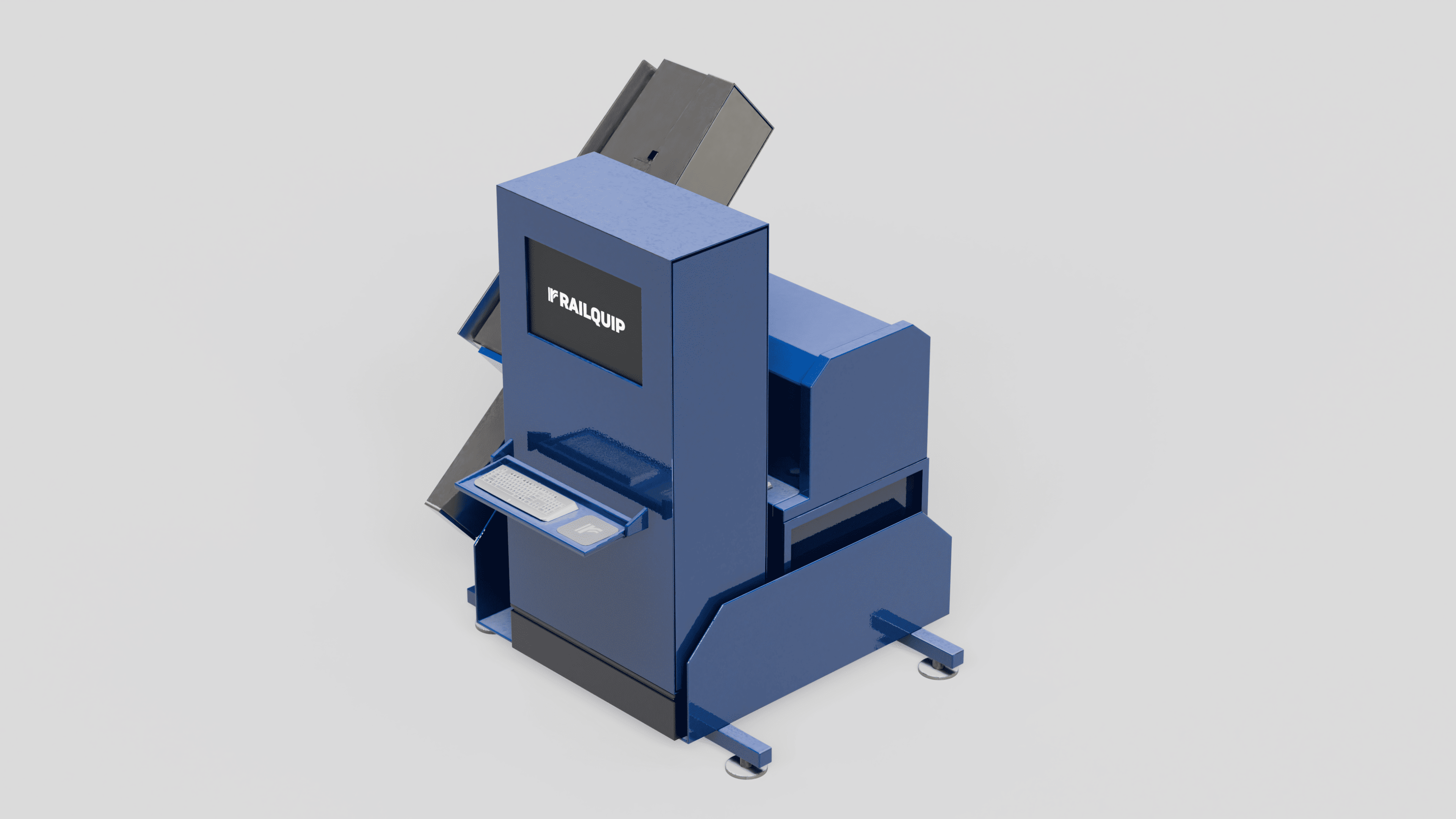

Railway Damper Testing Press

Purpose-built testing solution for precise measurement of railway damper performance and force dynamics.

Key Specifications

- Tests dampers 200-1200mm in length

- Up to 25kN force capacity

- Acceleration testing up to 20m/s²

- Servo motor-driven dynamic testing

—Technical Specifications

Overview

Our damper test press combines high-tech capabilities with space-efficient design, offering comprehensive testing and measurement features in a compact, user-friendly package.

Our NDT system delivers precise force measurements in relation to displacement and speed, utilizing state-of-the-art servo motor technology and a specialized ring measuring cell for superior accuracy.

The system supports testing according to international standards with comprehensive documentation, enabling efficient quality control for new, overhauled, and in-service dampers.

Features

Core testing capabilities

- Dynamic servo motor drive system

- Fully automatic angular position adjustment

- Integrated industrial-PC with PLC control

- Comprehensive force-speed relationship testing

Design advantages

- Compact footprint for minimum space requirement

- User-friendly control interface

- Maintenance-friendly design

- Fixed electrical cabinet installation

Testing range

- Damper length: 200-1200mm

- Maximum force: 25kN

- Maximum acceleration: 20m/s²

- Variable speed testing capabilities

Safety & Ergonomics

- Fully automatic test sequence

- Built-in operator safety features

- No additional barriers required

- Emergency stop with secure hold

- Power failure safety systems

—Related Projects

CERREJÓN COAL MINE IN COLOMBIA Case Study

To modernize Cerrejón’s lifting capabilities, Railquip and Eymaq provided a tailored solution: three sets of four 60-ton lifting jacks designed to replace outdated equipment

Washington Metropolitan Area Transit Authority – Case study

WMATA needed to replace its stationary drop table at the Shady Grove S&I shop due to excessive maintenance costs and aging parts. Railquip provided

Bay Area Rapid Transit Authority (BART) Case Study

BART required a solution to efficiently change the direction of railcars in their existing railyard. Railquip’s Automated Railcar Turntable provided a seamless, automated system

AMTRAK: Penn Station Rehabilitation Project Case Study

AMTRAK needed a custom-built Railbound Tunnel Crane for the New York Penn Station Rehabilitation Project. The crane had to operate within strict clearance limits

O-Train Case Study

In 2015, the O-Train in Ottawa, Canada, sought a complete train maintenance facility for their new fleet. Railquip provided a fully customized underground lifting

BNSF Burlington Northern Santa Fe Case Study

BNSF required a safer, more efficient way to pull locomotives over their wheel truing machine, addressing safety concerns and reducing pollution in the workshop.

Long Island Railroad Case Study

LIRR needed a safe and efficient solution for rerailing derailed trains due to frequent derailments that required costly external contractors. Railquip provided a standard

Clark Construction – Case study

In pursuit of operational excellence, our client sought to standardize maintenance practices across all locations with an established maintenance system featuring multiple turntables. The

TLC CASINO ENTERPRISES, INC.

Our task was to design, manufacture, and install a rotating bar floor in an existing 2nd-floor restaurant, taking into consideration the limitations imposed by