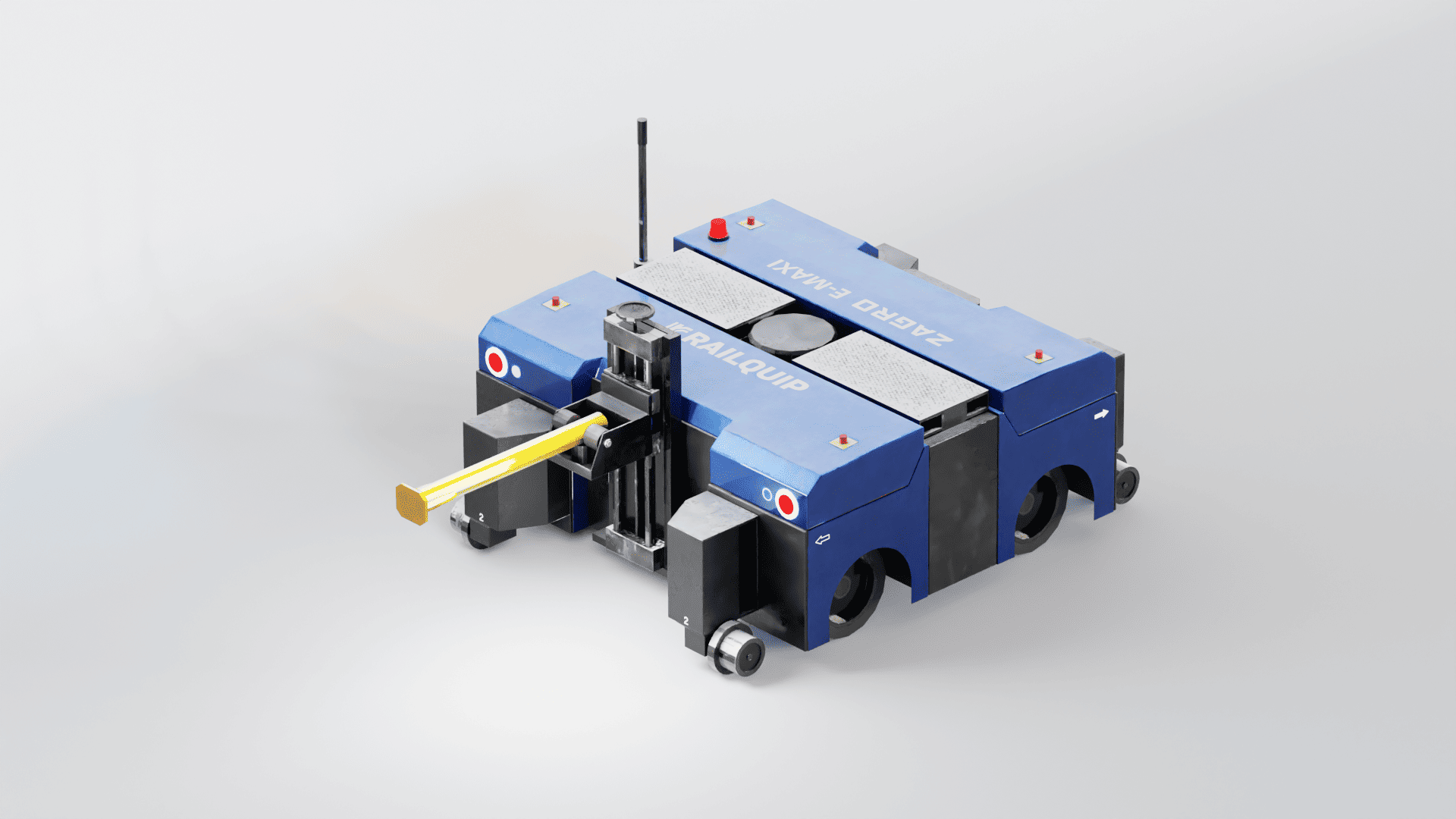

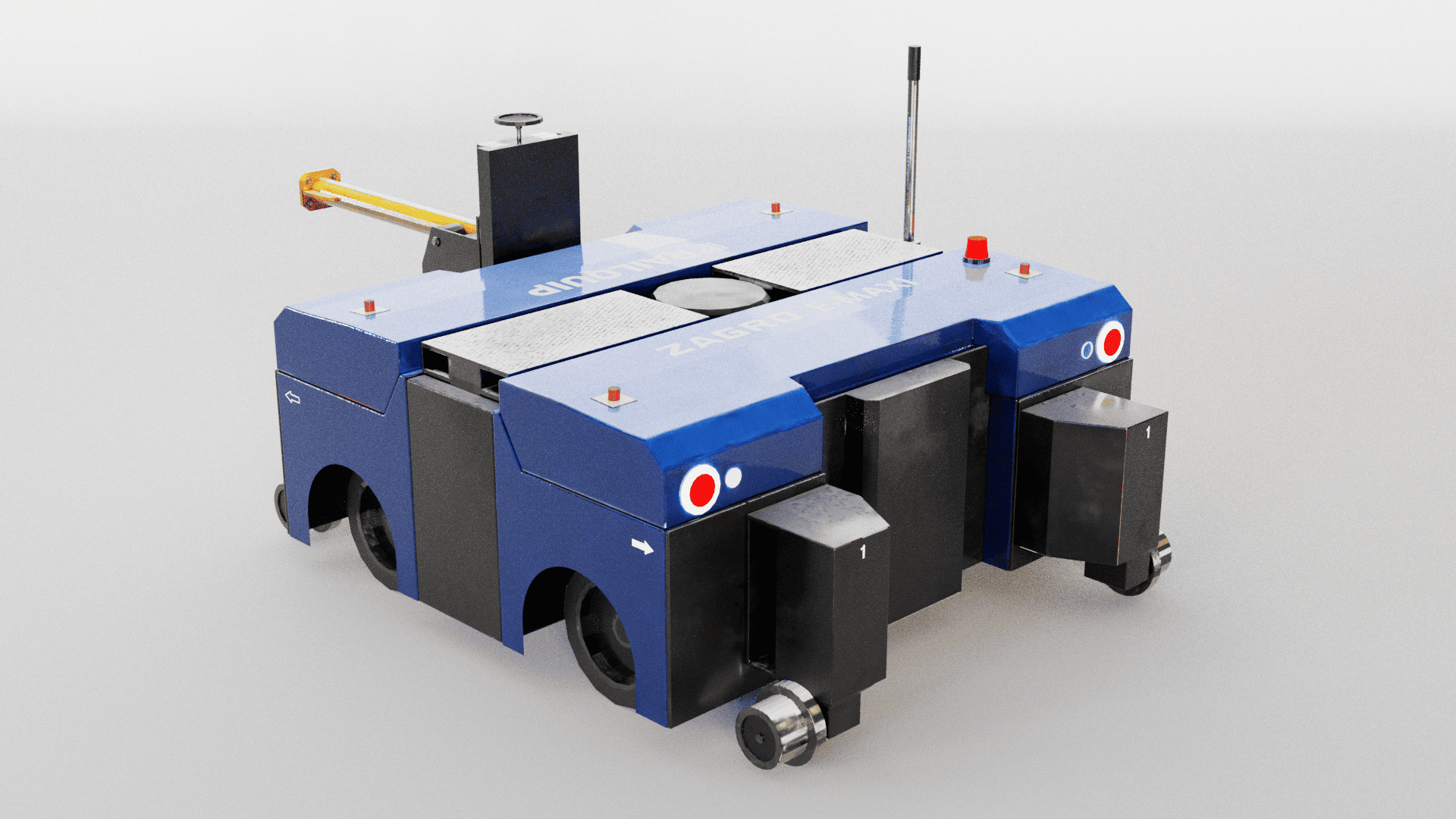

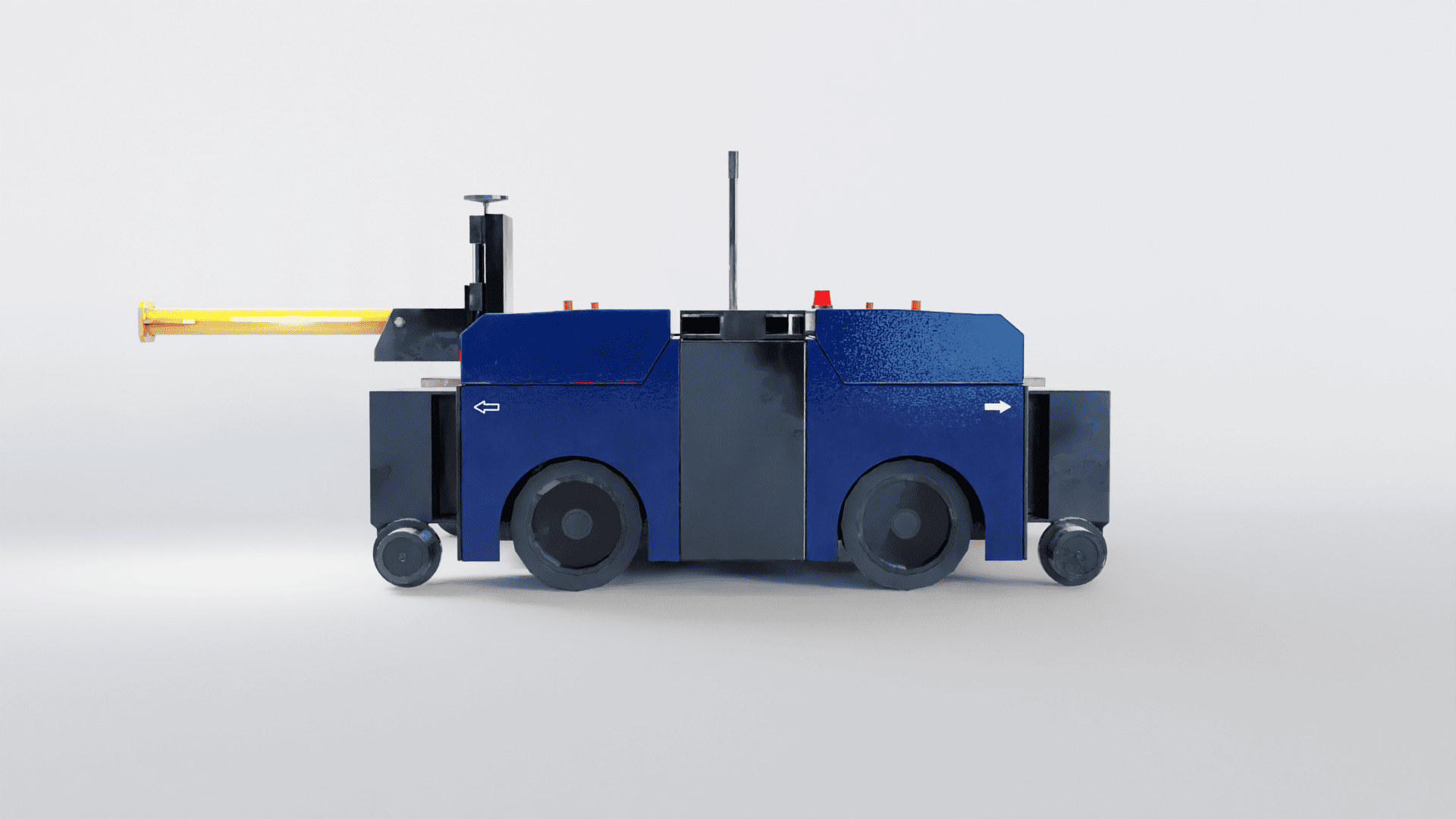

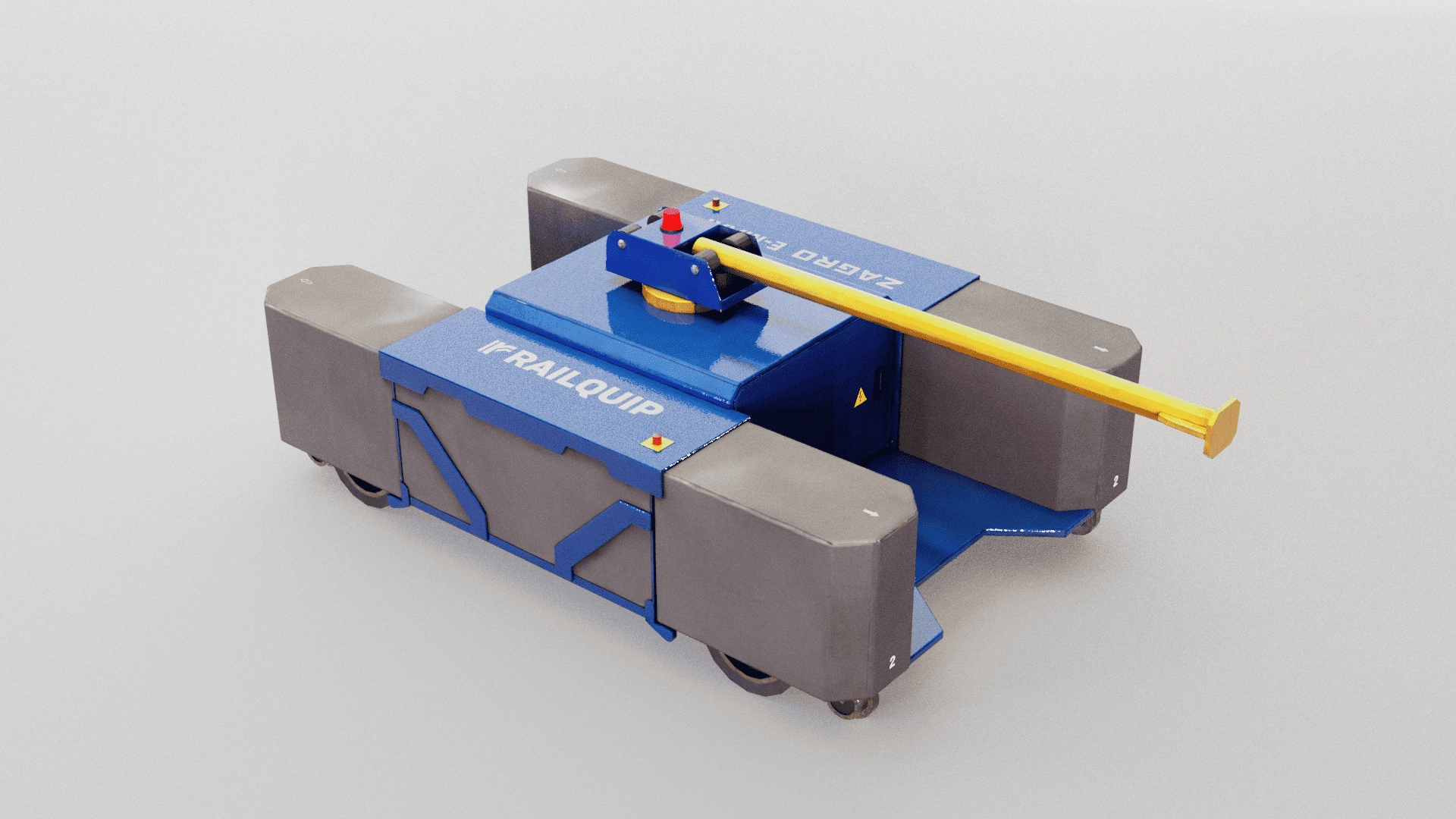

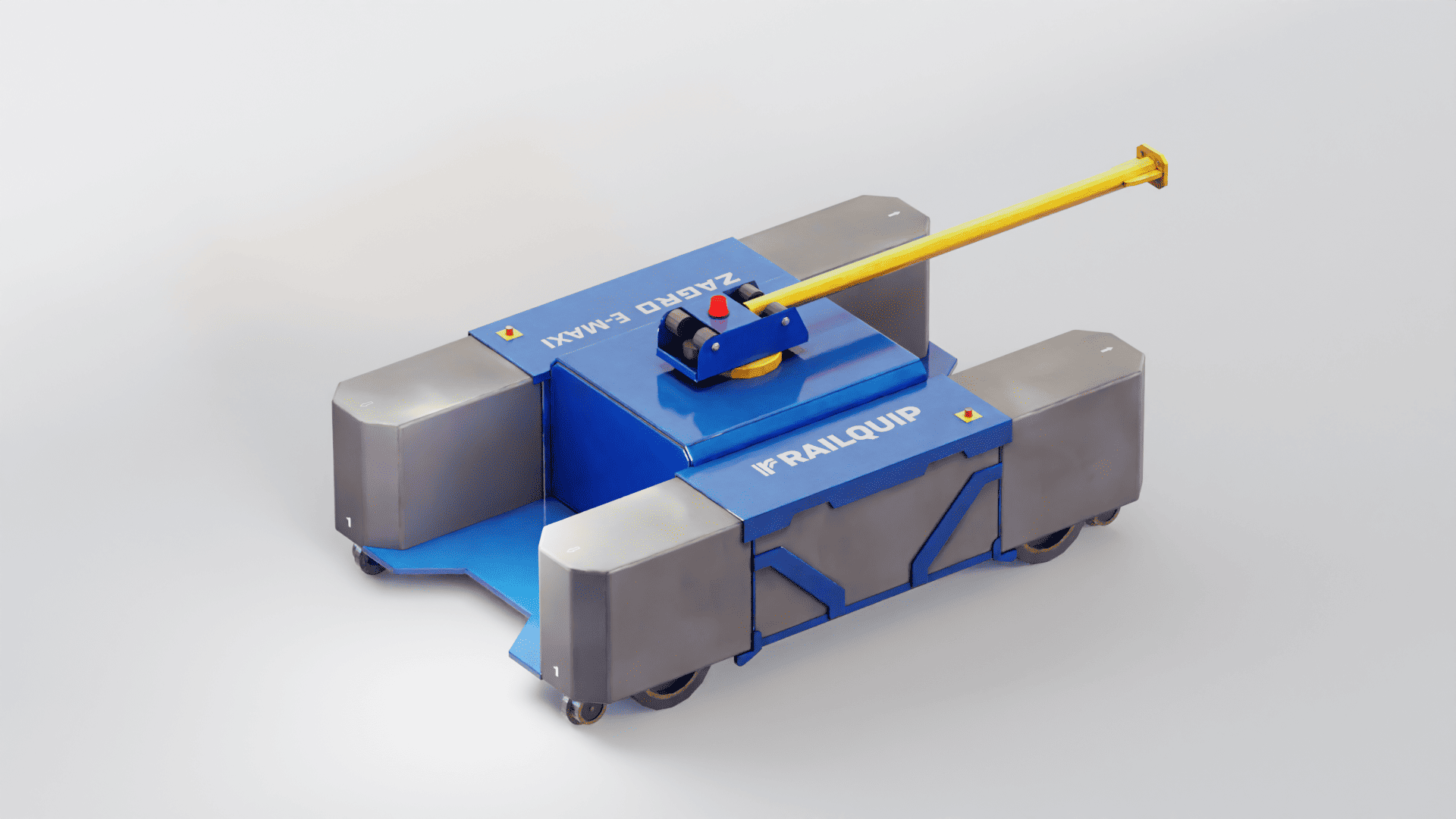

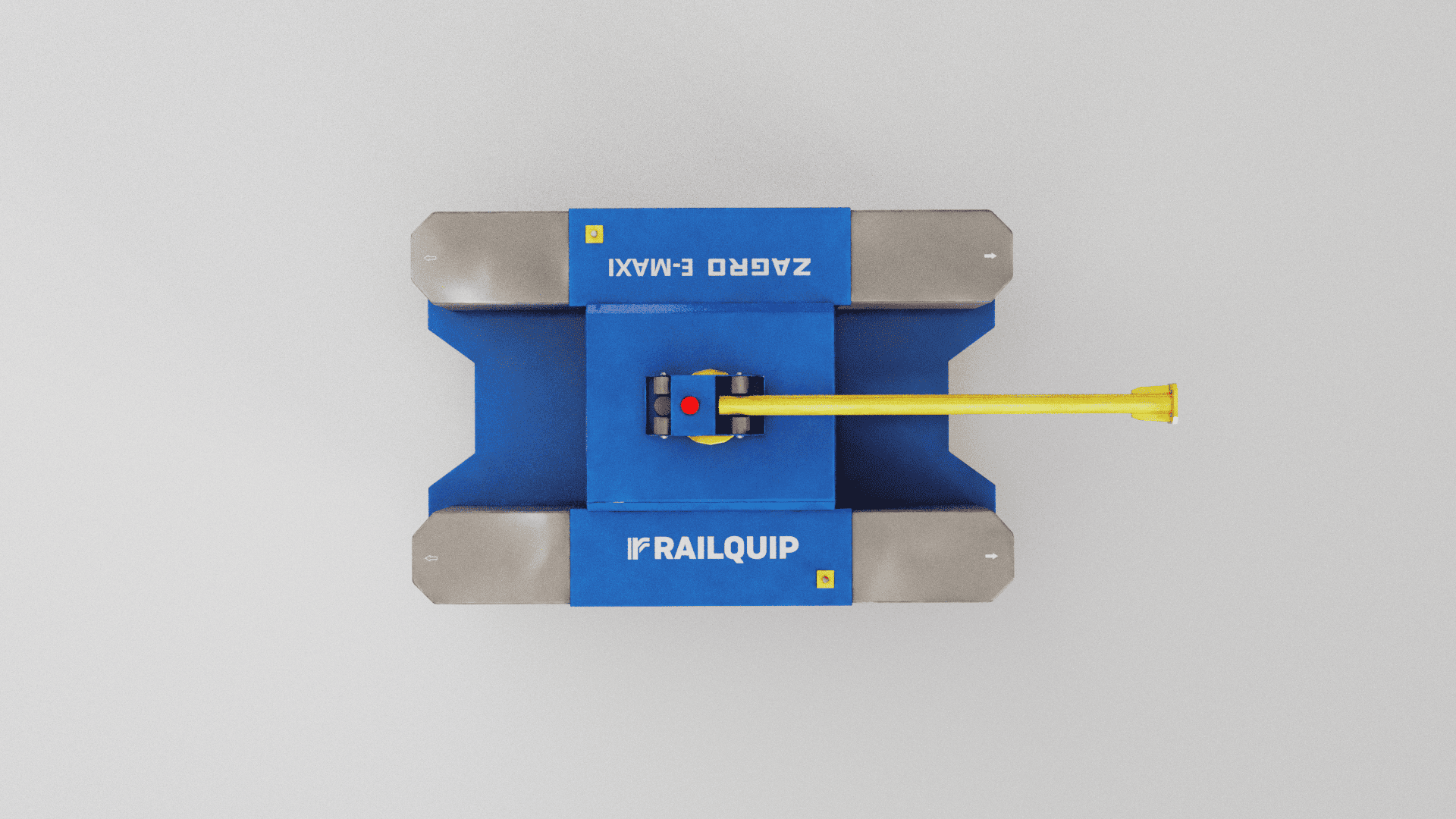

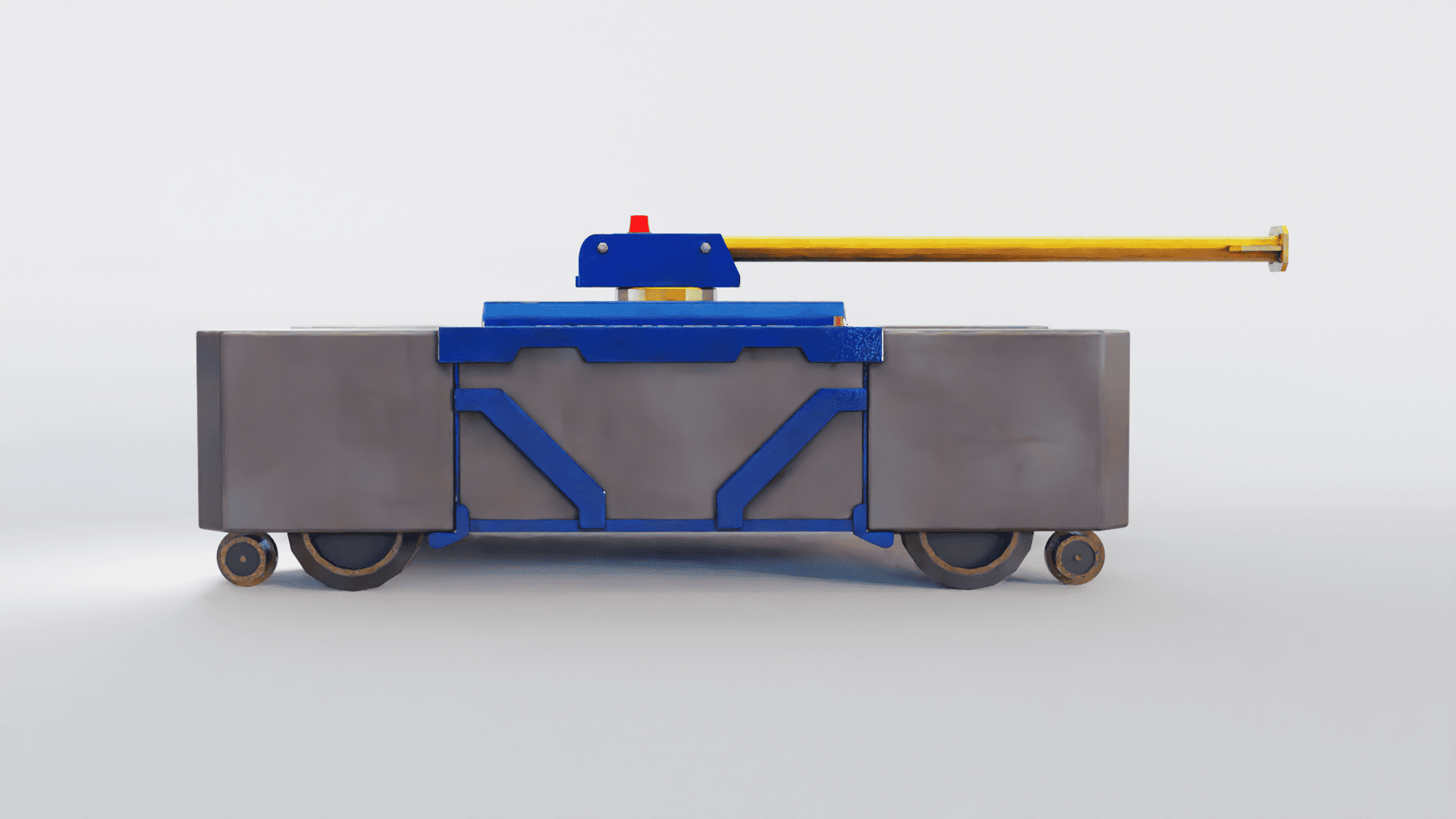

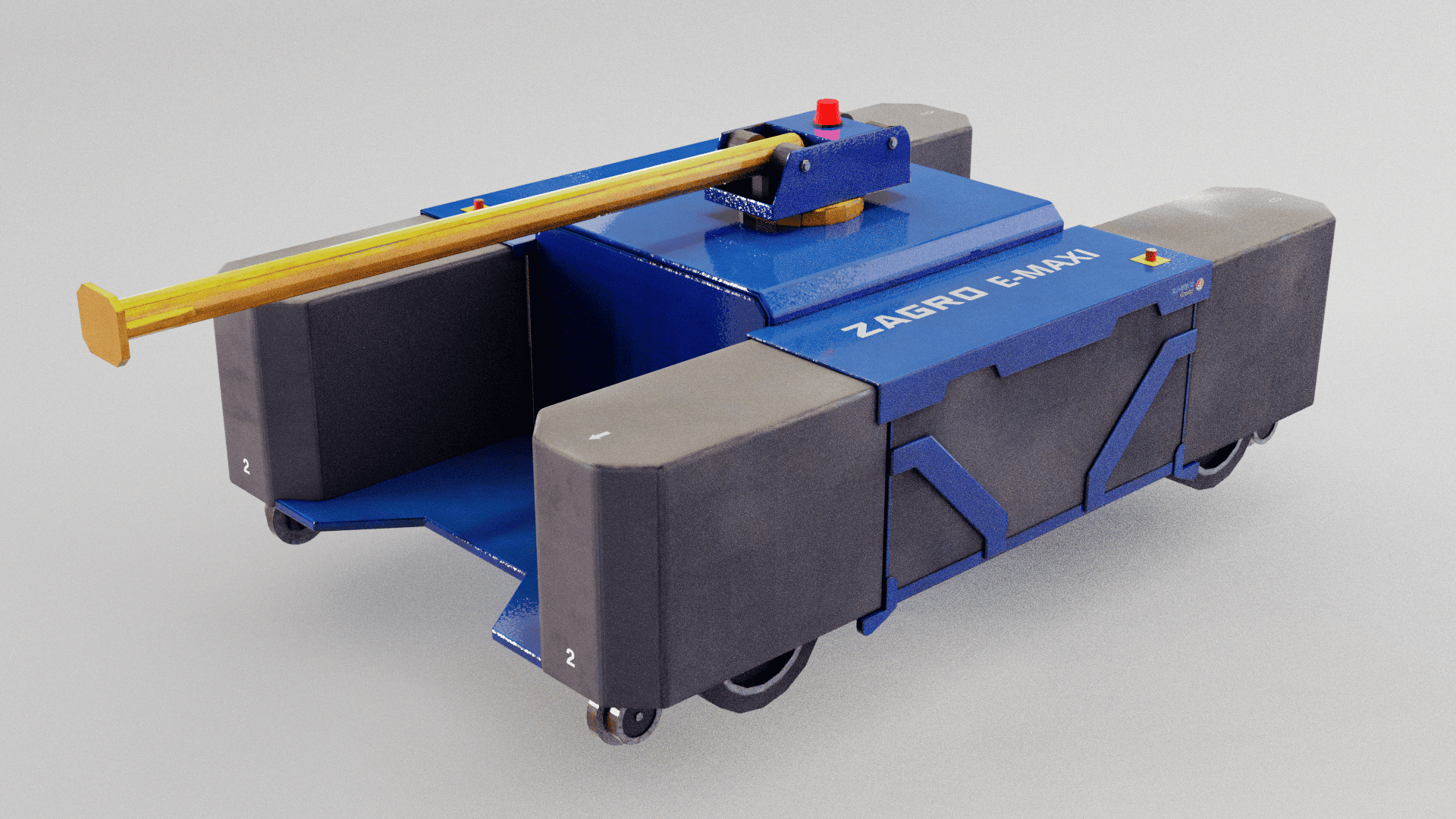

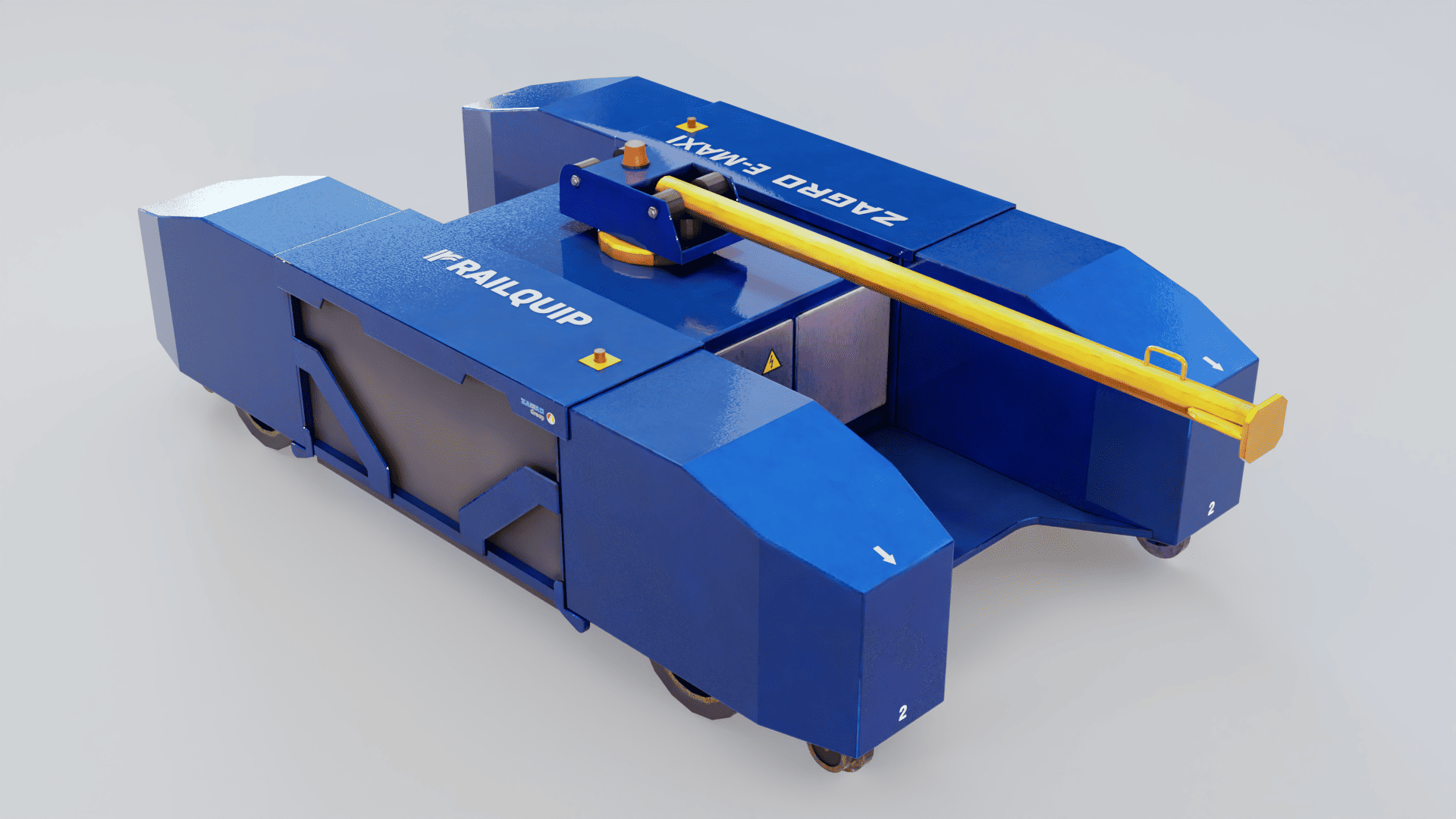

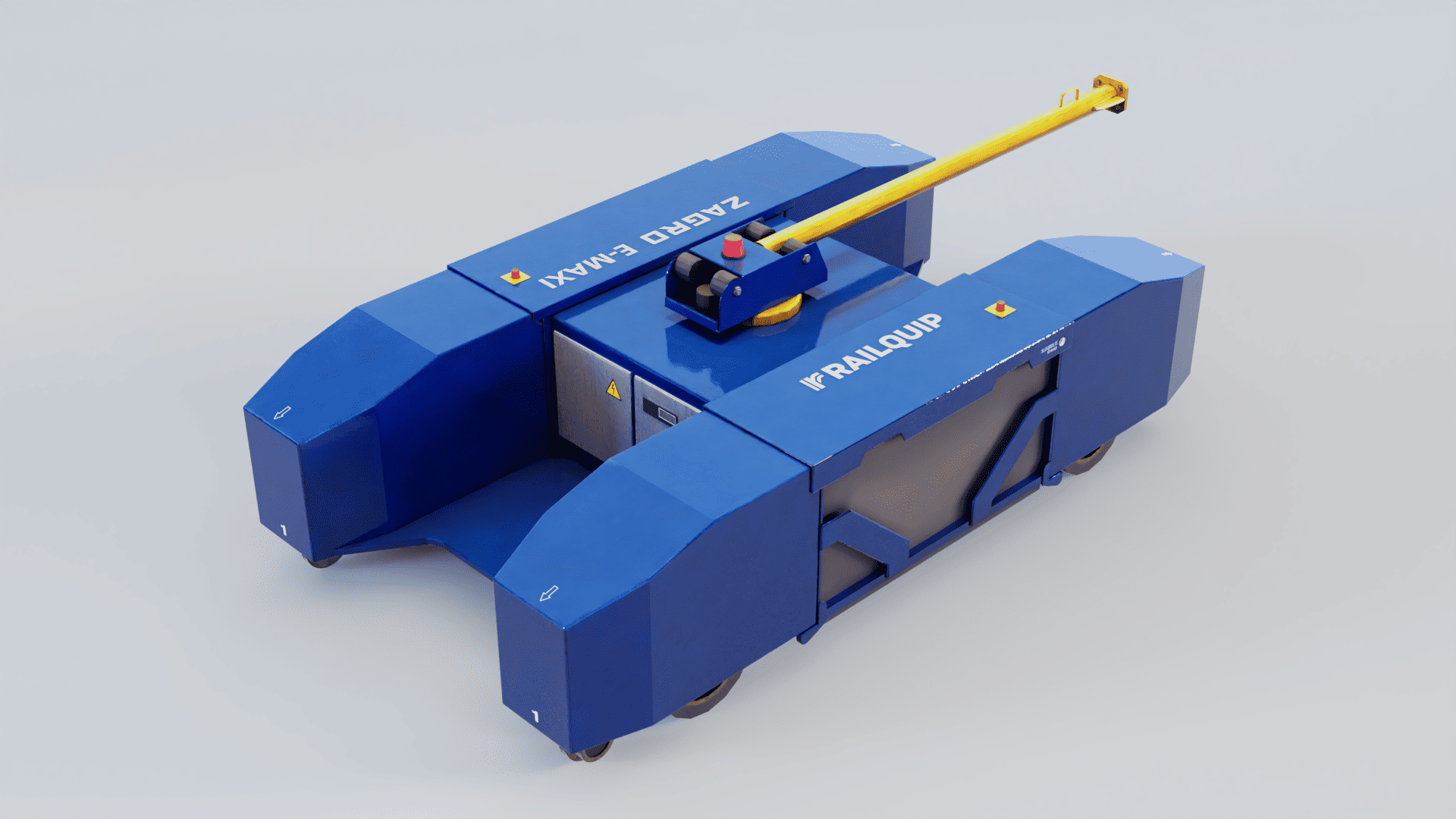

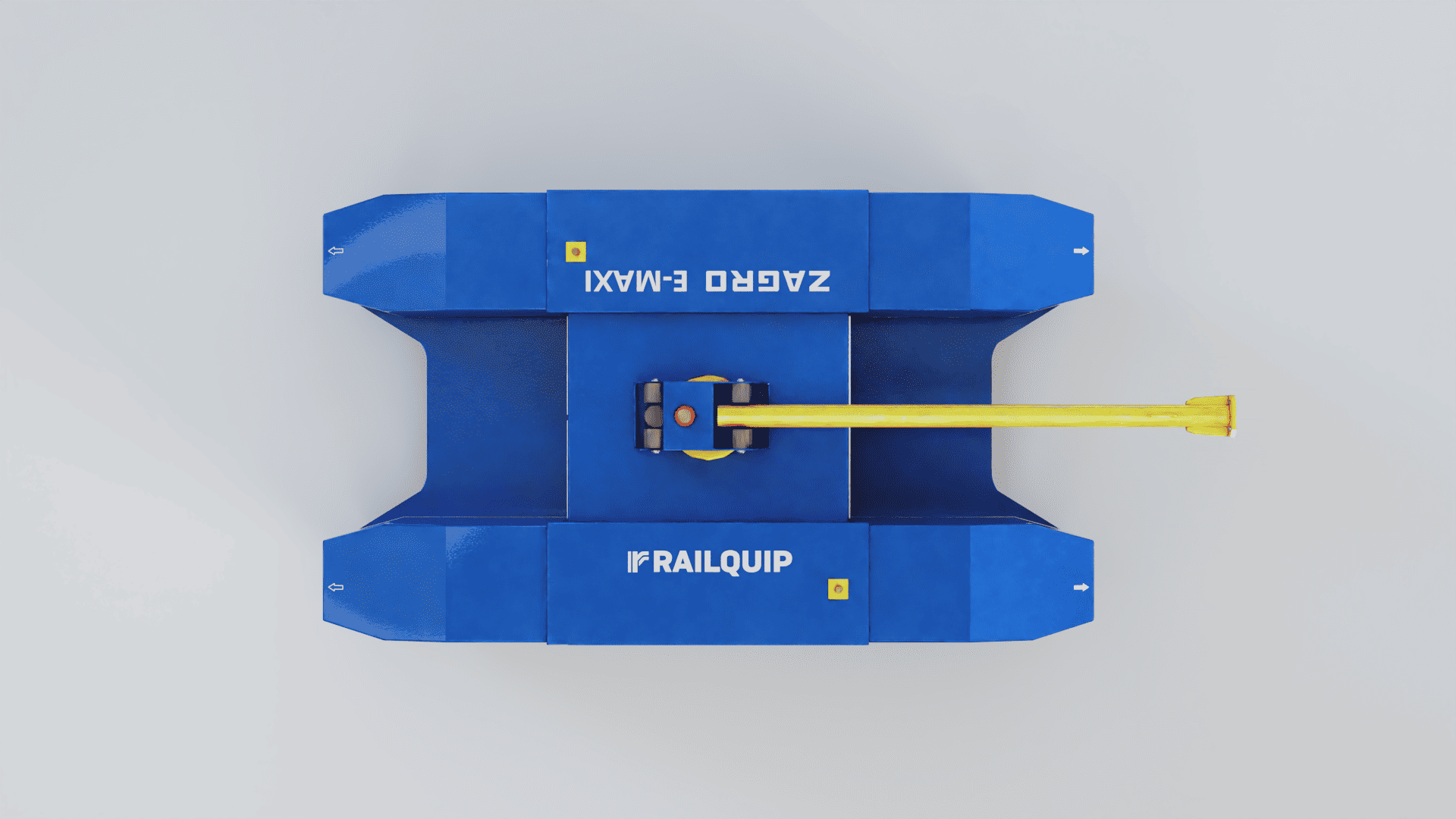

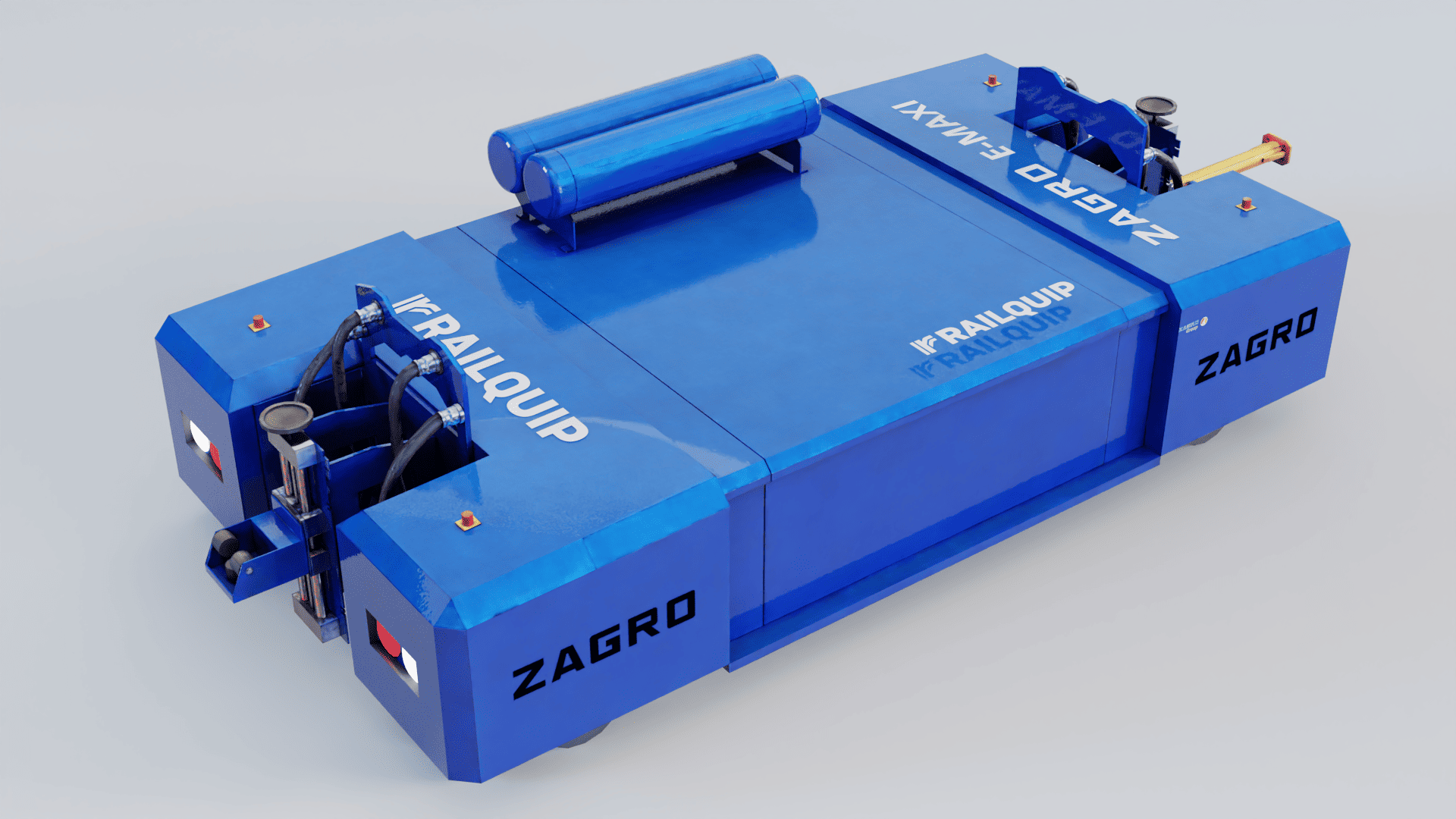

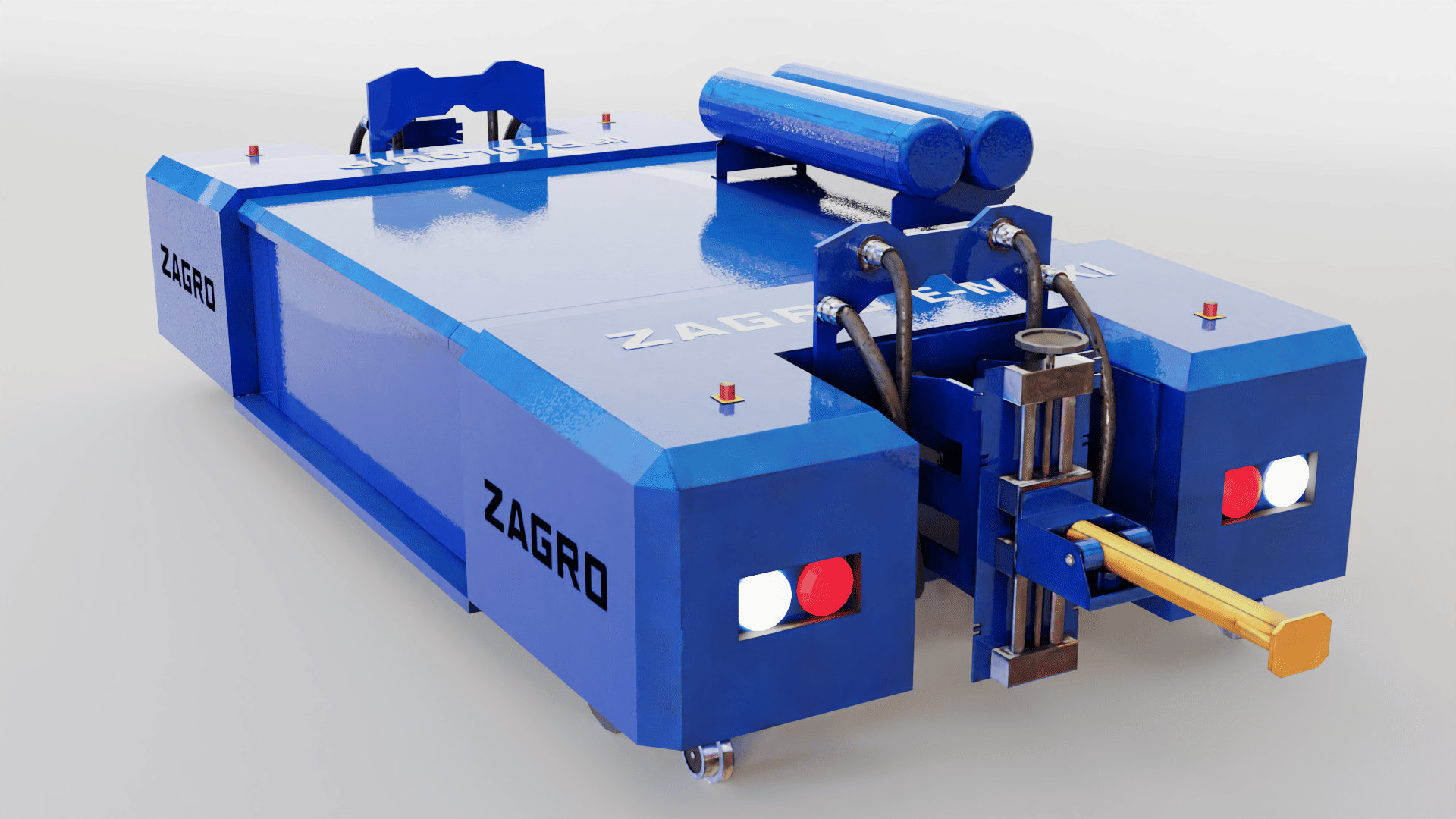

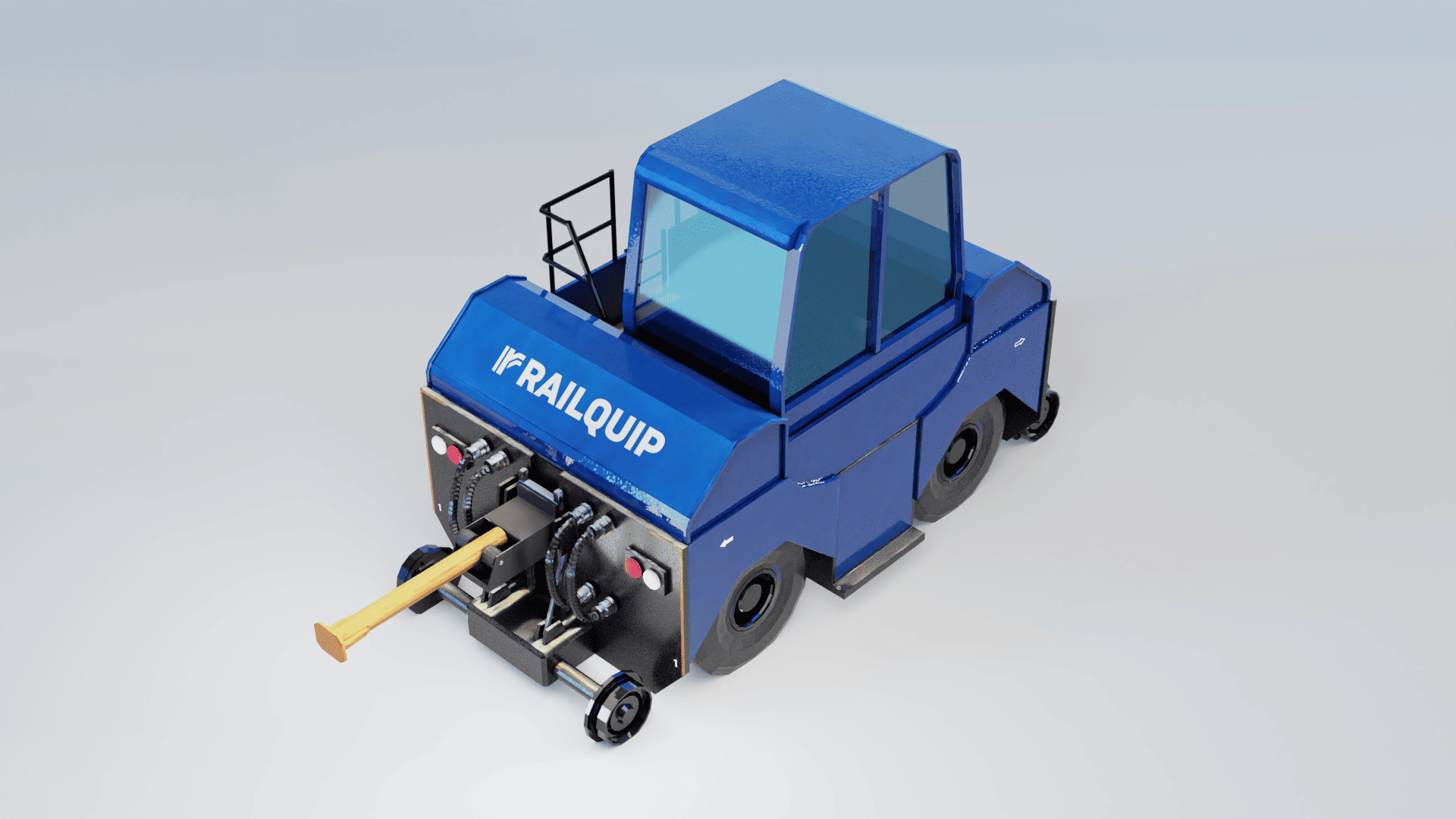

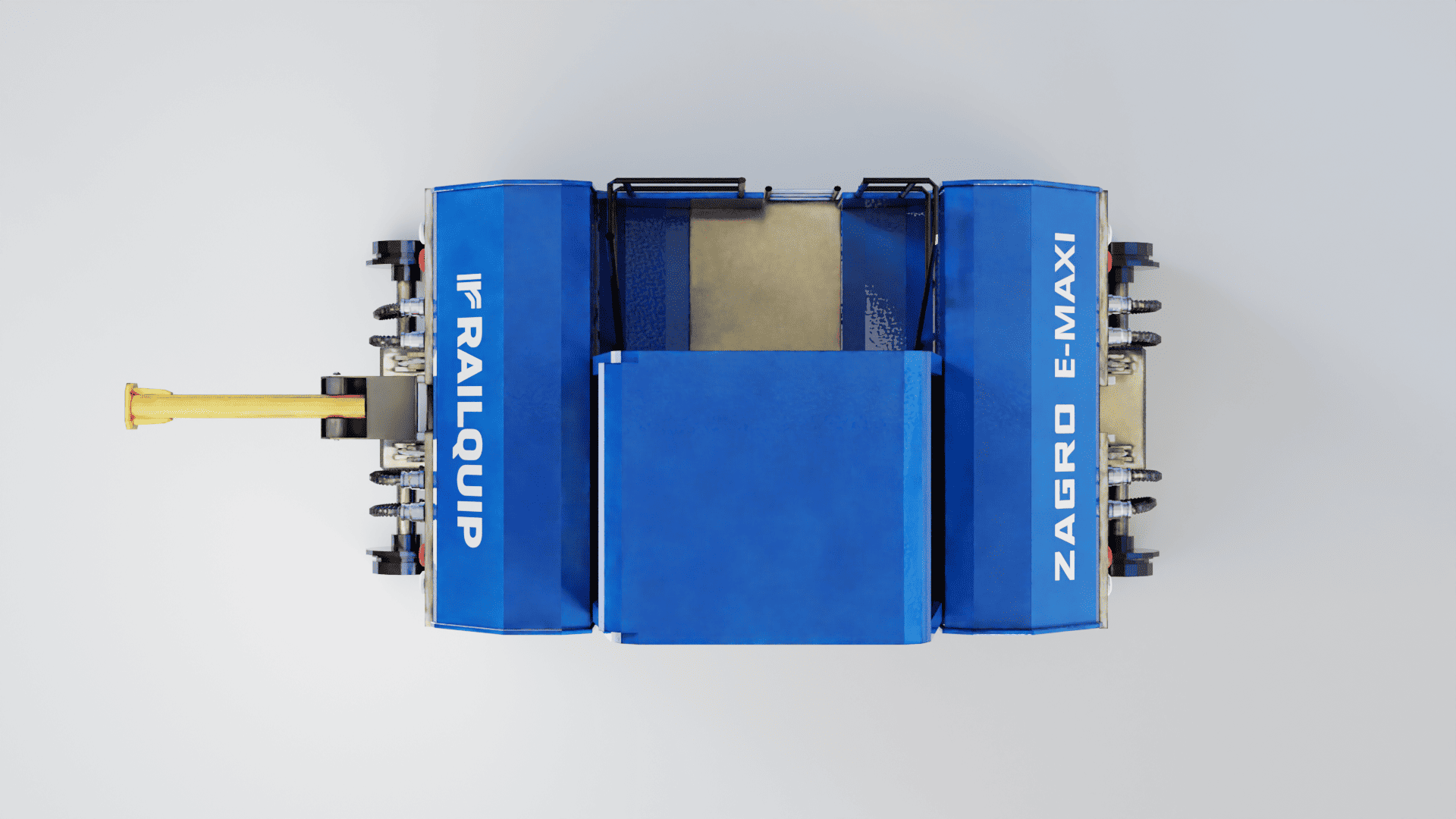

Battery Powered Railcar Mover (RC)- Emaxi Series

Emission-free, remote-controlled battery powered railcar mover with patented rail guidance and exceptional maneuverability – available in five capacities from 100 to 2000 tons

Key Specifications

- Five models: Emaxi S, M, L, XL, and XXL

- Towing capacities from 100 to 2000 tons

- Emission-free electric or hybrid operation

- 360° on-spot turns and 90° side-to-side movement

—Technical Specifications

Emaxi S – 100 Ton Capacity

- Drive Type: Battery (80V/5kW drive motors)

- Track Gauge: 1000 mm – 1676 mm

- Max. Trailer Load: 100 tons

- Traction at Hook: 5 kN

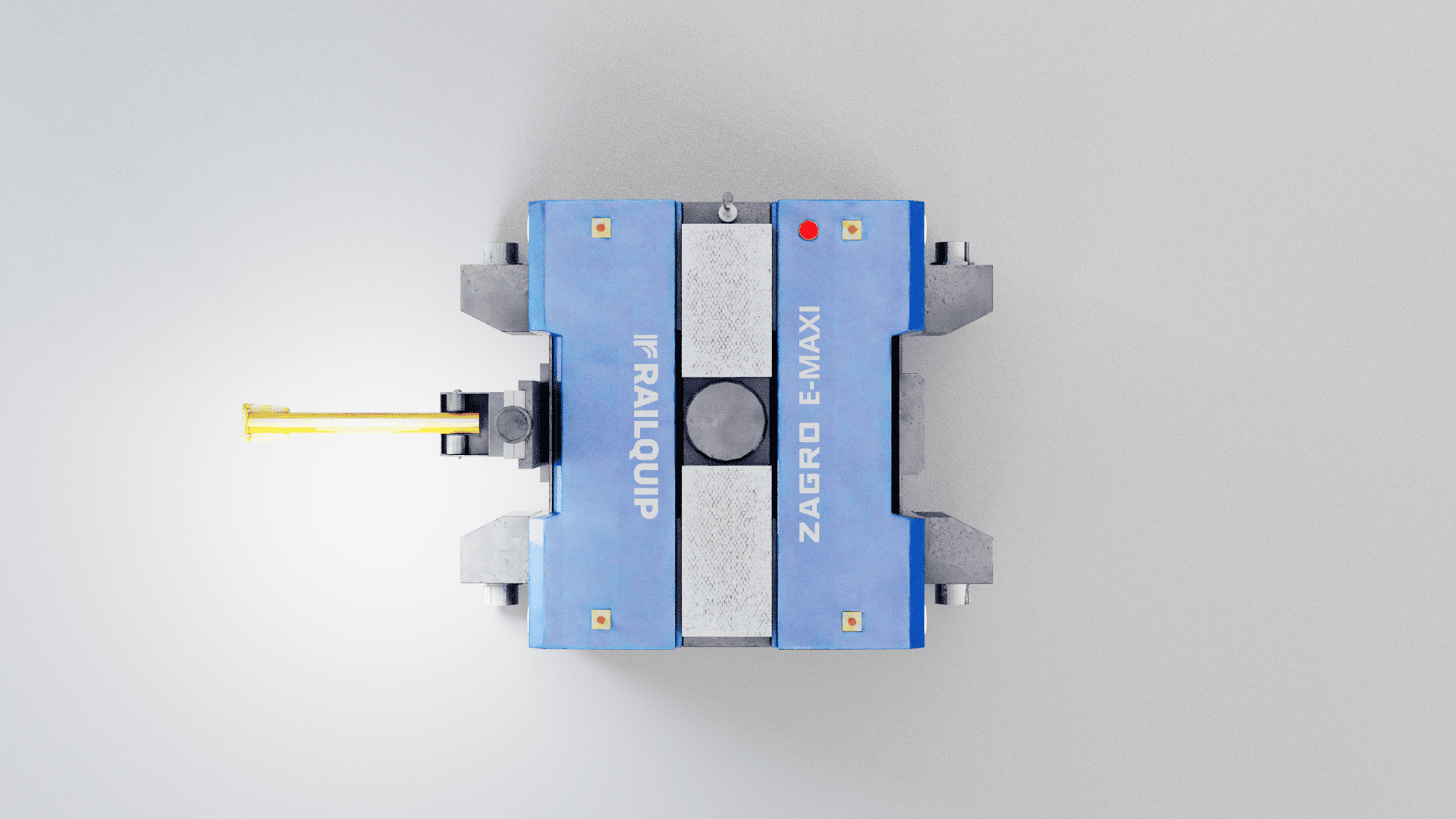

- Dimensions (L x W x H): 2200 x 2110/2170 x 1190 mm•

- Weight: 4300 kg

- Drive System: Two-wheel drive

Emaxi M – 300 Ton Capacity

- Drive Type: Battery (Four 80V/5kW motors)

- Track Gauge: 1000 mm – 1676 mm

- Max. Trailer Load: 300 tons

- Traction at Hook: 15 kN

- Dimensions (L x W x H): 2200 x 2110/2170 x 1190 mm•

- Weight: 4500 kg

- Drive System: Electric all-wheel drive

Emaxi L – 350 Ton Capacity

- Drive Type: Battery

- Track Gauge: 1435 mm – 1676 mm

- Max. Trailer Load: 350 tons

- Dimensions (L x W x H): 3580 x 2000 x 1320 mm

- Weight: 6500 kg

- Batteries: 2 x 625 Ah / 40 V

- Speed: 7.5 mph (without load), 3.25 mph (with load)

Emaxi XL – 700 Ton Capacity

- Drive Type: Battery

- Track Gauge: 1435 mm

- Max. Trailer Load: 700 tons

- Dimensions (L x W x H): 6390 x 2200 x 1760 mm

- Weight: 15,000 kg

- Batteries: 2 x 1000 Ah / 40 V

- Shunting Speed: 0–3 kph (solo), 0–6 kph (towing)

Emaxi XL Hybrid – 1000 Ton Capacity

- Drive Type: Hybrid• Track Gauge: 1000 mm – 1676 mm

- Max. Trailer Load: 1000 tons

- Traction at Hook: 50 kN

- Dimensions (L x W x H): 4230 x 2320 x 2820 mm

- Weight: 13,000-15,000 kg

- Generator: 18 kW

Emaxi XXL Hybrid – 2000 Ton Capacity

- Drive Type: Hybrid

- Track Gauge: 1435 mm – 1520 mm

- Max. Trailer Load: 2000 tons

- Dimensions (L x W x H):- Short wheelbase: 4300 x 2500 x 3300 mm- Long wheelbase: 5070 x 2500 x 3300 mm

- Weight: 24,000 kg

- Drive Motors: 4 x 80V/20kW

- Power Generator: 40 kW

- Batteries: 1085 Ah / 80V

- Max Speed: 15 km/h (road and rail)

Features

Common Benefits Across All Models

- Emission-free operation in workshops

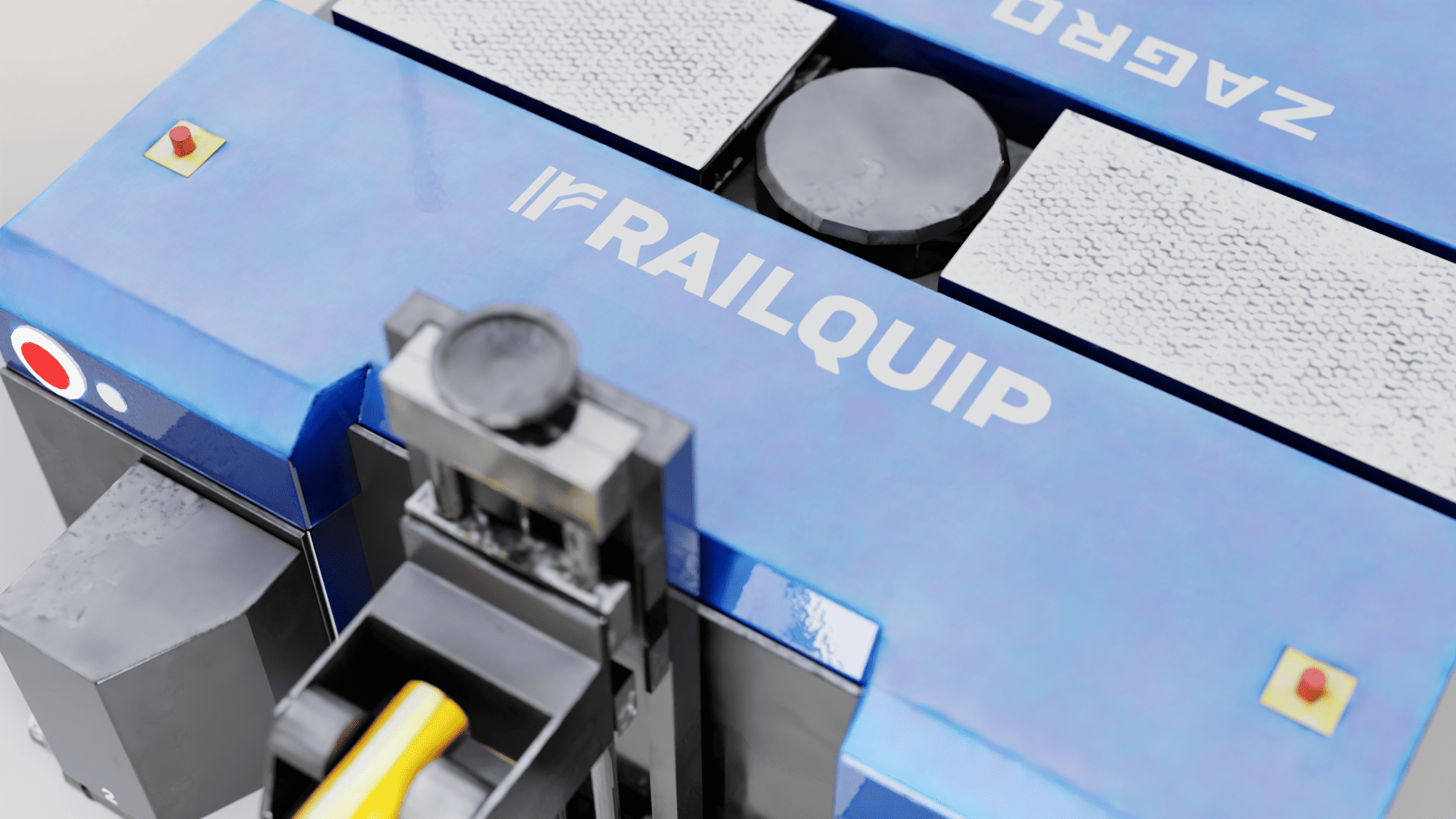

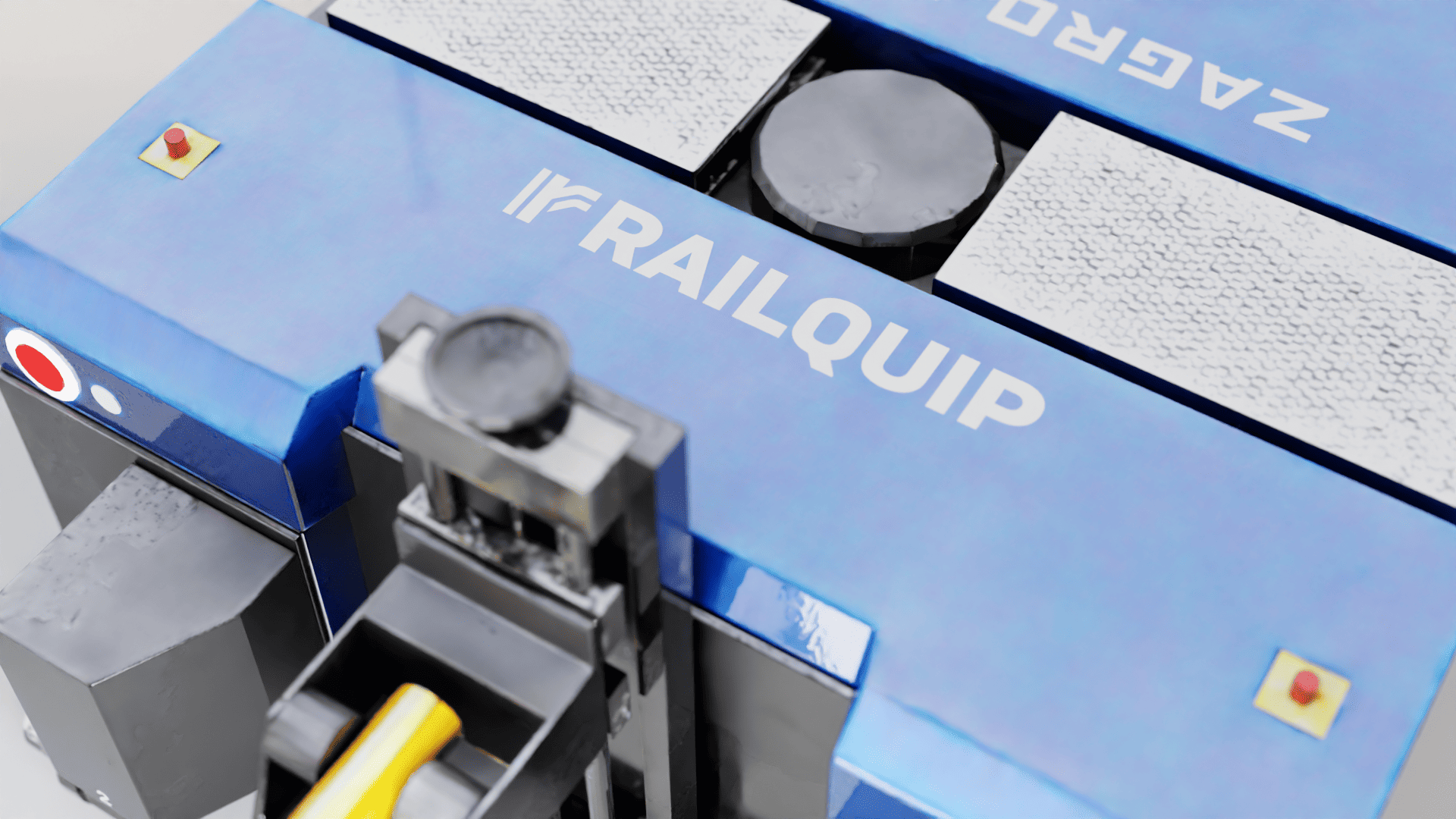

- Patented rail guidance for easy on/off tracking

- Reduced maintenance costs

- Quiet operation (minimal noise pollution)

- “Green” design concept (no air pollution)

- Not affected by fluctuating fuel costs

- Remote-controlled operation (range: 1,200 feet)

- Extreme maneuverability: 360° on-spot turns

- 90° side-to-side movement capability

- Meet Buy America Requirements

Control & Operation

- Radio remote control for one-man operation

- Two speed modes (slow: 0-3 km/h, fast: 0-6 km/h)

- Driving direction indicating LED lights

- Hydraulic track guiding system

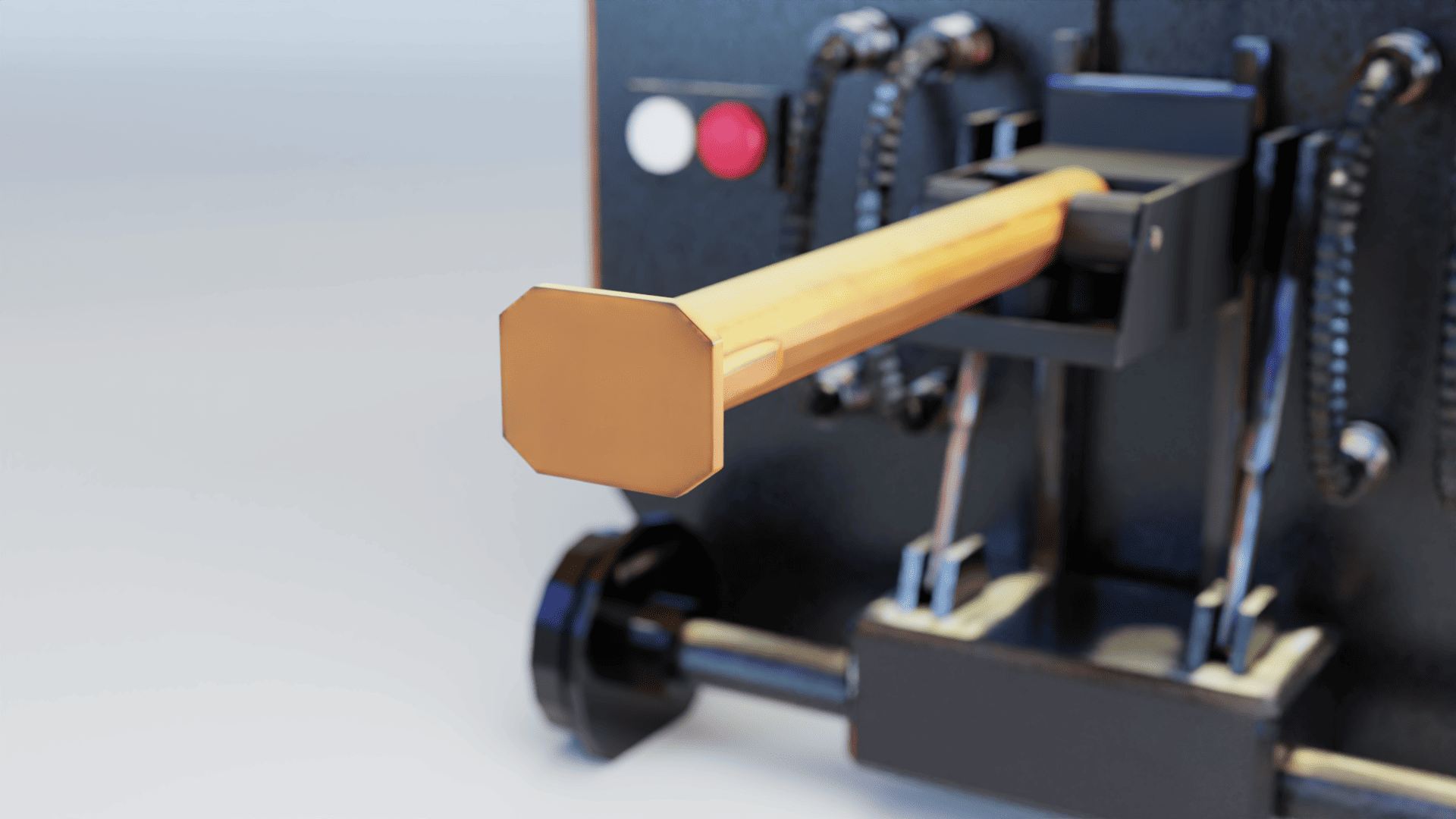

- Various coupling systems to suit different needs

- Adjustable coupler height mechanisms

Advanced Design Features

- Patented all-wheel steering system (M and larger)

- Energy recirculation during braking

- Diagonal steering for tracking in tight spaces (M)

- Circular steering for turning on the spot

- Double traction system for increased capacity

- Wagon brake system with compressor (XL and larger)

- Modern cabins with structured operating panels (larger models)

- Steel wheel systems for rail-bound operation (XXL)

- Camera systems for on-tracking (optional on XXL)

—Related Projects

CERREJÓN COAL MINE IN COLOMBIA Case Study

To modernize Cerrejón’s lifting capabilities, Railquip and Eymaq provided a tailored solution: three sets of four 60-ton lifting jacks designed to replace outdated equipment

Washington Metropolitan Area Transit Authority – Case study

WMATA needed to replace its stationary drop table at the Shady Grove S&I shop due to excessive maintenance costs and aging parts. Railquip provided

Bay Area Rapid Transit Authority (BART) Case Study

BART required a solution to efficiently change the direction of railcars in their existing railyard. Railquip’s Automated Railcar Turntable provided a seamless, automated system

AMTRAK: Penn Station Rehabilitation Project Case Study

AMTRAK needed a custom-built Railbound Tunnel Crane for the New York Penn Station Rehabilitation Project. The crane had to operate within strict clearance limits

O-Train Case Study

In 2015, the O-Train in Ottawa, Canada, sought a complete train maintenance facility for their new fleet. Railquip provided a fully customized underground lifting

BNSF Burlington Northern Santa Fe Case Study

BNSF required a safer, more efficient way to pull locomotives over their wheel truing machine, addressing safety concerns and reducing pollution in the workshop.

Long Island Railroad Case Study

LIRR needed a safe and efficient solution for rerailing derailed trains due to frequent derailments that required costly external contractors. Railquip provided a standard

Clark Construction – Case study

In pursuit of operational excellence, our client sought to standardize maintenance practices across all locations with an established maintenance system featuring multiple turntables. The

TLC CASINO ENTERPRISES, INC.

Our task was to design, manufacture, and install a rotating bar floor in an existing 2nd-floor restaurant, taking into consideration the limitations imposed by