Introduction

Rail yard operations are under more pressure than ever. With limited space, tight schedules, and complex maintenance needs, every delay can have a ripple effect on the network.

Traditional methods of turning railcars or locomotives often involve time-consuming, manual movements that eat up valuable space and expose workers to unnecessary safety risks.

That’s where railroad turntables come in. These powerful tools aren’t just for rotating rolling stock; they’re engineered to transform how space is used, how time is managed, and how maintenance flows from one track to the next.

In this blog, we explore how turntables address the core pain points of modern railyards and why investing in one could be the smartest decision you make this year.

The challenges of inefficient turning in rail yards

Turning railcars or locomotives isn’t as simple as it sounds, especially in a packed yard where space is already at a premium. Many operators rely on manual maneuvers or loop tracks, which take up time, increase wear on the system, and require more space than necessary.

Common issues include:

- Space constraints that limit routing options

- Slow manual repositioning that leads to bottlenecks

- Increased risk of accidents during complex maneuvers

- Inefficient yard flow, particularly during maintenance or reconfiguration

When rail yards grow or add new lines, these inefficiencies multiply. Without a fast way to redirect railcars, delays become routine and the entire yard pays the price.

How railroad turntables improve rail yard efficiency

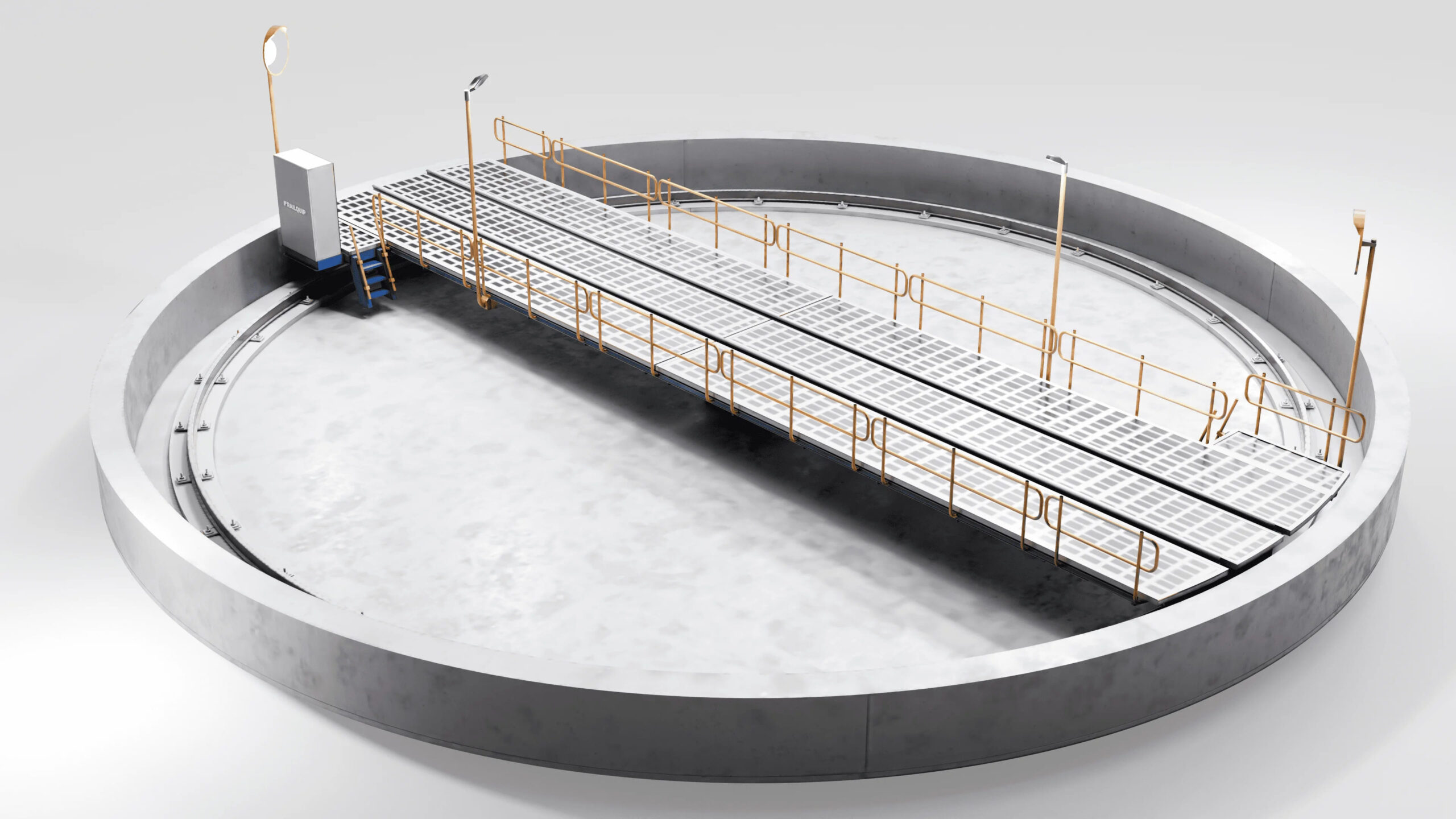

Turntables solve these issues by enabling a fast, 180° (or full 360°) turn in a compact footprint.

Instead of moving railcars through extensive loops or multi-track shifts, a turntable can rotate them in place and direct them back onto the desired track in seconds.

Here’s how that translates to real operational gains:

- Faster direction changes without complex shunting

- Compact design makes the most of limited yard space

- Less downtime for repositioning, which improves maintenance speed

- Improved safety by eliminating manual or reverse maneuvers

- Smoother yard flow, especially during peak activity

Railquip’s turntables are designed to integrate with existing tracks, pits, and service areas, making them ideal for retrofits or new yard builds.

Modern turntable technology: safety, precision, and automation

Today’s turntables go far beyond manual rotation. Railquip’s solutions are built with automated, sensor-driven control systems that provide fast, reliable operation with safety always at the forefront.

Key features include:

- Programmable positioning for precise railcar alignment

- Heavy-duty weight capacity, like the 50-ton turntable installed at BART

- Safety sensors and E-stop systems to protect crews and equipment

- Custom dimensions and finish to match your facility’s needs

- Turnkey installation for minimal disruption during setup

Whether you’re working with bogies, full locomotives, or railcars, modern turntables bring control, consistency, and future-ready design to the table.

Understanding the return on investment: why turntables pay off

Turntables may seem like a significant upfront investment, but the payback begins quickly, especially in busy yards where every minute of downtime impacts revenue.

Benefits to your bottom line include:

- Reduced fuel consumption and emissions from shorter, more direct routes

- Lower maintenance costs from less wear on tracks and rolling stock

- Higher throughput, enabling your yard to handle more movements per hour

- Increased worker safety, reducing the risk of injury and liability

- Future-proof infrastructure, ready for new railcar designs or expansion

With decades of performance and virtually no wasted movement, turntables help your facility run cleaner, faster, and smarter.

Case spotlight: how BART used a turntable to unlock maintenance flow

When Bay Area Rapid Transit (BART) needed a solution for a directional gap in their maintenance yard, they turned to Railquip. The goal was to rotate railcars quickly without major structural changes.

We delivered a 72-foot automated railcar turntable with a 50-ton capacity able to rotate full-size railcars 180 degrees as part of a fast, seamless process.

The result?

- Eliminated the need for inefficient routing loops and Wyes.

- Reduced time spent on maintenance maneuvers

- Increased safety with full automation and integrated controls

- A major performance upgrade without expanding the yard footprint

This is just one of several Railquip success stories. Each solution is designed around the client’s unique space, vehicle, and operational goals.

Conclusion

Railroad turntables are force multipliers for yard efficiency. By reducing movement time, improving safety, and optimising space, they help your team get more done with fewer delays and less risk.

Whether you’re operating a small regional yard or a major transit authority, the right turntable solution can transform your operations. And with Railquip, you don’t just get a product. you get a partner who understands the future of rail mobility.

Explore how a Railquip turntable can transform your rail yard.

Contact our team today to schedule a consultation and start designing a solution tailored to your space, weight capacity, and operational flow.