Introduction

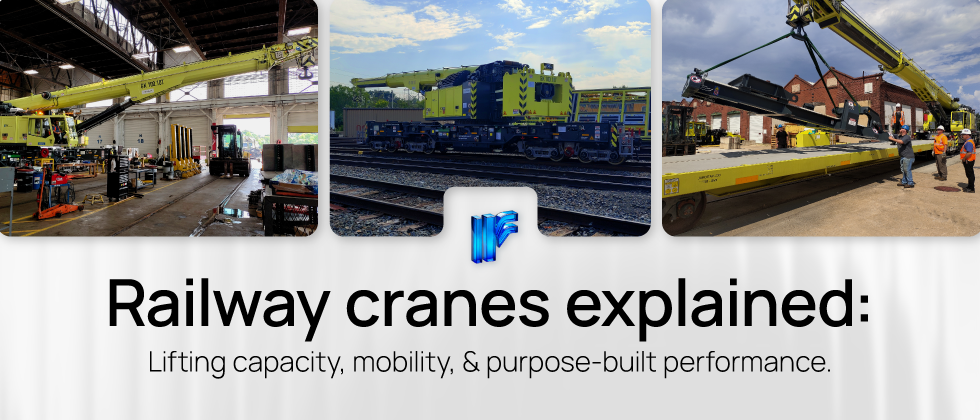

Railway cranes are essential to keeping major rail infrastructure projects moving, from lifting bridge sections and switch panels to completing complex tunnel work in constrained environments.

But choosing the right crane model isn’t just about weight capacity; it’s about finding the right fit for your site conditions, safety requirements, and operational timelines.

Some cranes are built for strength, others for flexibility and the most advanced combine both. Whether you need a telescopic rail-mounted giant or a mobile unit that can adapt to changing terrain, understanding the different types of railway cranes is key to making the right investment.

What are the most common types of railway cranes used today?

Railway cranes are used across a wide range of projects, from emergency recovery to planned infrastructure installation. The most common categories include:

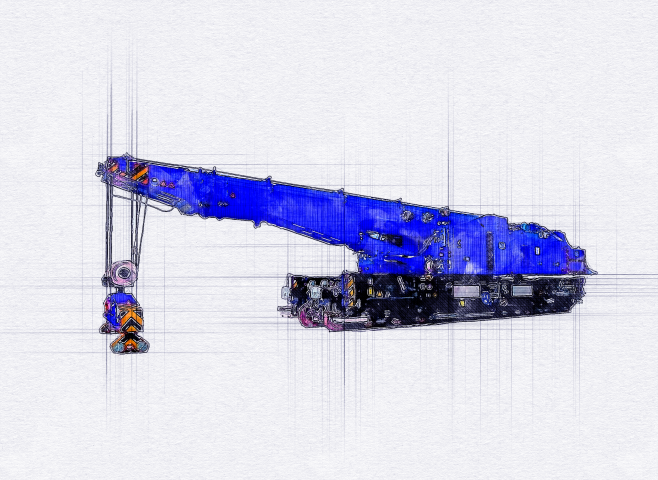

- Rail-mounted telescopic cranes: Purpose-built to travel on tracks and handle heavy lifting (up to 172 tons). Ideal for bridge sections, switch panels, and large-scale installations.

- Mobile cranes with switch tilters: Versatile, road-to-rail units designed for fast setup and adaptability across different locations.

- Tunnel and underpass cranes: Compact and engineered for precision lifting within tight clearance envelopes, including under catenary lines or overhead obstructions.

- Custom crane systems: Designed and fabricated to address specific site constraints, often paired with tilt cars or lifting fixtures.

Each type can be adapted to suit different environmental demands, from open rail yards to underground stations.

Fixed vs. mobile railway cranes: how do they compare?

The key difference comes down to mobility and flexibility. Fixed (railbound) cranes provide unmatched stability, capacity, and integration with existing rail infrastructure, while mobile cranes offer speed, adaptability, and faster deployment.

Fixed railway cranes are best for:

- Sites with dedicated rail access

- High-frequency lifting operations

- Projects requiring high lifting capacity and precision

- Environments where track-mounted stability is critical

Mobile cranes, on the other hand, are designed to:

- Move between job sites easily

- Operate in varied terrain or access-restricted areas

- Support temporary or short-term lifting needs

- Pair with other equipment like tilt cars or lifting fixtures

Railquip’s offering includes both types and can even design hybrid setups if your project demands the best of both.

Lifting capacity matters: what weight should your crane handle?

Not all cranes are created equal when it comes to load capacity. Choosing a crane with insufficient lifting power can lead to safety hazards, project delays, and equipment failure.

Railquip’s cranes are engineered for:

- Loads up to 172 tons, making them some of the strongest telescopic railway cranes available

- Precision handling of large track panels, switch components, and bridge sections

- Smooth operation even in superelevated curves, under catenary systems, or tight working conditions

When evaluating capacity, consider not only the heaviest load you’ll handle, but how often, where, and under what space constraints it will need to be lifted.

The power of rail-mounted cranes: why versatility is key

Rail-mounted cranes offer more than just brute force, they’re designed for precision, adaptability, and long-term deployment. These cranes navigate existing tracks with ease, and modern versions come equipped with:

- Advanced safety and stability systems to protect personnel and equipment

- Customisable specs based on project requirements

- Compatibility with switch tilters, tilt cars, and modular lifting gear

- High maneuverability even in tight or electrified environments

With the right rail-mounted setup, you get both lifting strength and operational agility, especially critical for projects with tight windows or minimal disruption tolerance.

Are certain brands more reliable when it comes to railway cranes?

Absolutely! And in high-stakes rail projects, reliability isn’t optional. The best-performing railway cranes come from manufacturers with proven track records in both engineering and field-tested durability.

At Railquip, we work exclusively with GK Rail Service, one of the leading OEMs for railway cranes worldwide. Their systems are known for:

- Robust construction designed to withstand harsh conditions and long-term use

- Precision manufacturing that ensures seamless integration with tilt cars, switch tilters, and advanced control systems

- Adaptability for specialised projects, including tight tunnel work and electrified rail networks

- Global support with parts, maintenance, and engineering expertise backed by decades of experience

Our cranes don’t just meet expectations — they exceed them under pressure. And with full North American support through Railquip, clients get the benefit of both world-class equipment and local partnership.

Case spotlight: AMTRAK’s tunnel crane solution for Penn Station

In one of the most challenging operational environments in North America, AMTRAK needed a crane that could operate within the tunnels of New York’s Penn Station, beneath catenary lines, within limited vertical clearance, and under strict safety regulations.

The solution: a custom-built 110-ton railbound tunnel crane model, developed in partnership between Railquip and OEM partner GK Rail Service.

Key features:

- Designed for clearance envelopes unique to NY Penn Station tunnels

- Able to load and unload switch panels in tight spaces with precise orientation

- Paired with tilt cars and lifting fixtures for enhanced flexibility

- Delivered and commissioned amid global supply chain disruptions

This project highlights Railquip’s ability to design and deliver custom-engineered crane systems under complex logistical and technical constraints with lasting value for national rail infrastructure.

Conclusion

From fixed telescopic cranes to mobile lifting systems, the right railway crane model can dramatically improve project safety, speed, and precision.

The key is matching the equipment to your task, capacity needs, and site conditions and working with a provider who understands the full scope of railway demands.

Railquip offers a full portfolio of railway cranes backed by expert consultation, OEM partnerships, and on-site support. If you’re looking for power, precision, and long-term reliability, we’ve got your lift covered.

Talk with our team today and get a custom solution tailored to your railway project’s size, complexity, and timeline choosing the best railway crane model.