In today’s rail operations, not every task requires the complexity, cost, and infrastructure demands of a traditional locomotive.

While locomotives remain essential for long-haul movement and high-capacity freight, they’re frequently misused for short-distance shunting, in-yard switching, and workshop operations.

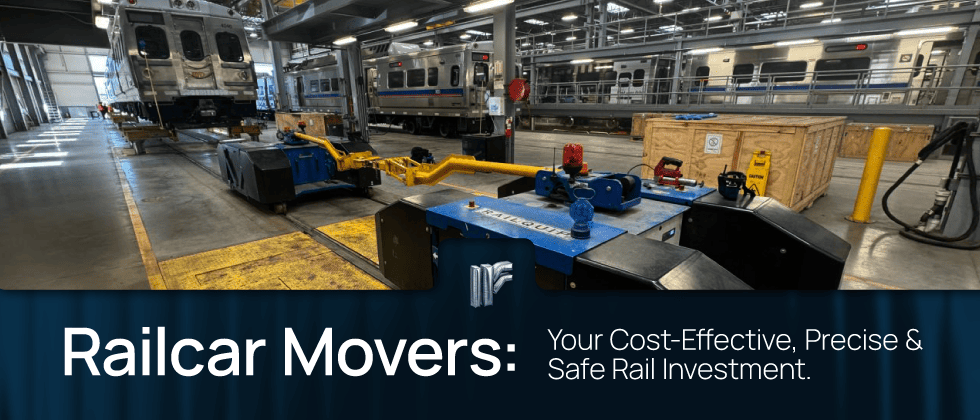

That’s where railcar movers come in. Purpose-built to bridge the gap between full-scale engines and manual alternatives, modern railcar moving systems are rapidly becoming the standard for controlled, low-emission, and cost-efficient operations.

Whether battery-powered, LPG-driven, or forklift-integrated, these units are reshaping how rolling stock is positioned, inspected, and maintained, especially in dense or constrained spaces.

Let’s break down exactly what a railcar mover is, the available types, how they compare to locomotives, what capacity they handle, and why their long-term operational benefits go far beyond initial cost savings.

Understanding Railcar Movers: Purpose-Built for Precision, Not Haulage

A railcar mover is a compact, rail-capable machine designed to move locomotives, freight cars, or transit vehicles over short distances. Unlike a switcher locomotive typically built for heavier, multi-car movements—railcar movers are engineered to deliver:

- Controlled push/pull force for specific railcar segments

- Operation in confined environments like workshops, yards, and terminals

- Faster positioning cycles with fewer personnel

- Low-speed precision rather than line-haul traction power

Many modern railcar movers, such as those in Railquip’s E-Maxi Series, are fitted with remote control operation, diagonal steering, and battery-powered systems for noise-free, emission-free indoor use.

This difference in form and function allows a railroad car mover to be integrated directly into daily maintenance or industrial workflows, where deploying a full locomotive would be costly, overengineered, and inefficient.

A Versatile Lineup: Railcar Mover Types by Power, Size, and Application

Railcar movers aren’t one-size-fits-all. There’s an increasing range of models designed to meet capacity, budget, and environment-specific needs. Railquip offers a full line of electric railcar movers, alongside LPG-powered and forklift-compatible units.

Battery Powered Railcar Movers

The E-Maxi M, for example, is a battery powered railcar mover with:

- A 300-ton trailer load capacity

- Four 80V/5KW electric motors (all-wheel drive)

- Track gauge adaptability (1000 mm to 1676 mm)

- Remote control operation with 0–6 km/h dual-speed modes

- Zero-emission design for indoor workshops and closed environments

- Energy recirculation on braking, reducing consumption and heat build-up

- Coupler height adjustment, making it compatible with varied rolling stock

These units are ideal for transit authorities, repair facilities, ports, and any operation requiring emission-free railcar pulling equipment.

LPG / Gas Railcar Movers

Railquip also distributes LPG-based models for applications where battery downtime is a concern, and indoor emissions aren’t a limiting factor. These offer multi-directional control, push/pull operation, and up to 220 tons of load capacity, with drastically reduced infrastructure requirements compared to yard switchers.

Forklift-Powered & Portable Railcar Movers

Where budgets are tight or frequency is low, forklift-powered railcar movers provide a compact, low-maintenance option for short shunting jobs. Mounted onto standard forklifts (2–7 tons), they operate at up to 3.1 mph on standard gauge and require minimal operator training.

Across all categories, Railquip also supports railcar mover rentals, used railcar movers for sale, and custom parts, making the solution scalable to most operational sizes.

Key Advantages Over Traditional Locomotives: Why Railcar Movers Win in Yard Operations

Traditional locomotives are built for freight, not finesse. Using them for yard movement means consuming diesel, requiring certified engineers, occupying large track footprints, and accelerating track wear.

In contrast, modern railcar movers, especially the remote-controlled, battery-powered systems, offer tangible benefits:

- Cost efficiency: Electric models eliminate fuel costs, reduce staffing needs, and cut maintenance overhead.

- Improved safety: Remote control systems remove the operator from hazardous positions. In the BNSF case, Railquip’s E-Maxi L replaced unsafe shunting practices, enabling safe movement over a wheel truing machine inside a confined shop environment.

- Extreme maneuverability: Circular and diagonal steering systems enable 360° turns and side-to-side movement without realignment.

- Reduced infrastructure strain: Lightweight builds generate less track fatigue, especially on workshop-grade rail.

- Emissions compliance: With no combustion involved, battery models meet indoor air quality standards and are unaffected by fuel market volatility.

Simply put, a railcar shunter is purpose-built for what locomotives were never meant to do: switch, position, and move rolling stock in tight spaces with total control.

Capacity and Performance: How Much Can They Really Move?

One of the most common misconceptions about railcar moving systems is that they can’t handle real operational loads. That’s not only outdated, it’s inaccurate.

The E-Maxi M, as detailed in Railquip’s technical sheet, can tow up to 300 metric tons on level track, with a traction force of 15 kN. With four motors delivering all-wheel drive and battery-fed torque, these units don’t just move empty cars, they reposition fully loaded rolling stock in industrial, transit, and workshop settings.

Performance isn’t just about raw pull, it’s also about adaptability:

- Track gauge flexibility (from 1000 mm to 1676 mm)

- Modular coupling systems (e.g. Schaku, hook-and-pin, or hydraulic)

- Remote operation up to 1200 ft

- Fine-speed control from 0 to 6 km/h for delicate movements

These specs make railcar movers ideal for operations where space is limited, precision is required, and equipment wear must be minimised. They’re already deployed in diverse environments—from light rail depots to heavy freight maintenance shops—because they do the job without overbuilding.

Long-Term Cost Efficiency: Railcar Movers Are an Operational Investment

The financial argument is simple: railcar movers replace overbuilt systems with purpose-driven efficiency.

Compared to switcher locomotives, a battery-powered mover from Railquip offers:

- Lower acquisition cost: especially for operations that don’t need line-haul power

- Reduced operating costs: no fuel, no exhaust aftertreatment, lower brake wear

- Minimal maintenance: with sealed drivetrains and fewer moving parts

- Smaller crew requirements: one trained technician can handle remote operations

- Better ROI in low-mileage applications, where traditional equipment would idle or be underutilised

And because Railquip offers both railcar mover parts and technical support, lifecycle management is simplified. Replacement is modular, documentation is clear, and downtime is reduced.

In short, these aren’t disposable machines, they’re engineered systems that save money over time while improving safety and control.

Railcar Movers Offer What Locomotives Can’t—Precision, Control, and Efficiency

Traditional locomotives were never designed for the environments that make up most of today’s railcar movement needs: tight yards, indoor maintenance facilities, or terminals where emissions, space, and crew size matter more than top speed or hauling power.

Yet many operations continue using them in these settings, accepting higher costs, reduced safety, and inefficient workflows as unavoidable. Railcar movers change that.

They offer a tool that’s engineered for short-distance precision, not long-haul strength. They reduce fuel consumption to zero (in the case of battery-powered units), require less operator training, and drastically lower the wear on track infrastructure and rolling stock components.

Features like remote control, load-specific traction, and adaptive steering make them more responsive to today’s real operational demands—not just legacy practices.

When operations rely on mobility, predictability, and safety, not brute force, a railcar moving system becomes not just a smart choice, but the only logical one.

And that’s where Railquip stands out.

From transit authorities to Class I freight shops, Railquip delivers railcar movers designed for the environments you actually work in:

- Wheel truing bays with limited clearance

- Indoor depots requiring zero emissions

- Industrial yards where movement must be precise and repeatable

- Urban light rail systems where noise and control matter more than speed

Every mover we build is supported with technical documentation, spare part access, and engineering flexibility—so you’re not locked into a single configuration or forced to overbuild for your task.

Stop using oversized machines for small, precise jobs.

If you’re repositioning rolling stock, maintaining transit fleets, or shunting railcars in tight spaces, you don’t need a locomotive, you need equipment designed for the task.

Railquip’s electric and LPG-powered railcar movers combine power with control, safety with flexibility, and efficiency with long-term cost savings.Traditional locomotives were never designed for the environments that make up most of today’s railcar movement needs: tight yards, indoor maintenance facilities, or terminals where emissions, space, and crew size matter more than top speed or hauling power.

Yet many operations continue using them in these settings, accepting higher costs, reduced safety, and inefficient workflows as unavoidable. Railcar movers change that.

They offer a tool that’s engineered for short-distance precision, not long-haul strength. They reduce fuel consumption to zero (in the case of battery-powered units), require less operator training, and drastically lower the wear on track infrastructure and rolling stock components.

Features like remote control, load-specific traction, and adaptive steering make them more responsive to today’s real operational demands—not just legacy practices.

When operations rely on mobility, predictability, and safety, not brute force, a railcar moving system becomes not just a smart choice, but the only logical one.

And that’s where Railquip stands out.

From transit authorities to Class I freight shops, Railquip delivers railcar movers designed for the environments you actually work in:

- Wheel truing bays with limited clearance

- Indoor depots requiring zero emissions

- Industrial yards where movement must be precise and repeatable

- Urban light rail systems where noise and control matter more than speed

Every mover we build is supported with technical documentation, spare part access, and engineering flexibility—so you’re not locked into a single configuration or forced to overbuild for your task.

Stop using oversized machines for small, precise jobs.

If you’re repositioning rolling stock, maintaining transit fleets, or shunting railcars in tight spaces, you don’t need a locomotive, you need equipment designed for the task.

Railquip’s electric and LPG-powered railcar movers combine power with control, safety with flexibility, and efficiency with long-term cost savings.

Whether you’re searching for a permanent upgrade, a portable solution, or reviewing railcar movers for sale, Railquip gives you the systems, and the support, to move smarter.

Talk to our team today and get the railcar mover that matches your operation, not someone else’s legacy: www.railquip.com