1. What are railroad lifting jacks and why are they essential to railway operations?

Before we get into choosing between portable or fixed systems, it’s important to understand what railroad lifting jacks actually do and why they matter.

These types of equipment are the unsung heroes of maintenance operations. Whether you’re lifting a car body, swapping a bogie, or performing undercar inspections, the right jack system keeps crews safe and tasks efficient.

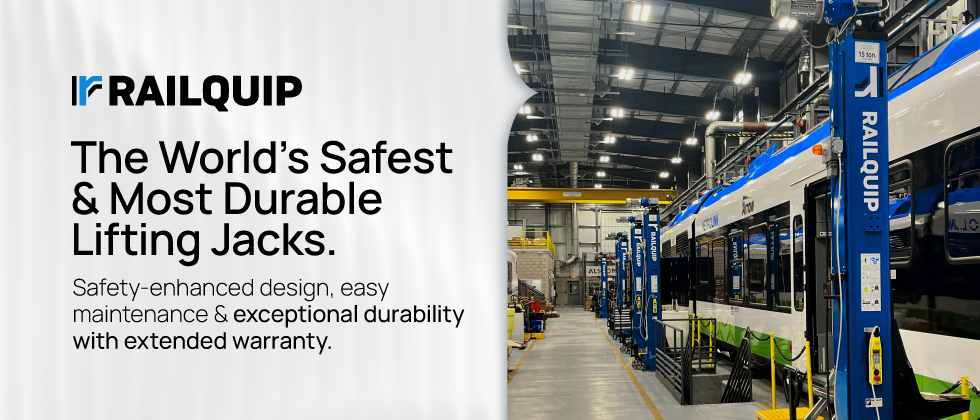

Railquip’s lineup includes jack systems that go beyond basic lifting. Each unit is built to meet the demands of modern rail service environments, from light rail to heavy freight, with features that prioritise safety, uptime, and operator control.

Key advantages include:

- Enhanced safety features including load sensors, nut wear detection, and steel safety follower nuts

- Automatic lubrication and ISO 9000-certified quality assurance

- Equipment lifespans of up to 30 years, backed by a 2-year warranty

- Flexible configurations for both workshop integration and field deployment

2. Understanding the differences: portable vs. fixed railroad lifting jacks

Now let’s break down the two main types of lifting systems: portable lifting jacks and fixed installations. While they share the same core function (lifting) the way they work, where they’re used, and how they support operations are quite different.

Choosing between the two isn’t just about power, it’s about context. How your team works, where your assets are located, and how often lifting is required should all shape your decision.

Here’s a closer look:

Portable jacks:

- Can be moved by hand, forklift, or overhead crane

- Typically sold in sets of four or more, controlled via a central control console

- Include pendant controllers for real-time monitoring and local control

- Ideal for modular setups or mobile teams who need flexibility

Fixed jacks:

- Stationary units typically installed in maintenance pits or workshops

- Offer superior precision and lifting stability

- Often tied into underfloor hoists or drop table systems

- Better suited for high-volume maintenance facilities or long-term infrastructure

3. When to choose portable lifting jacks: flexibility, mobility, and modular control

If your team operates in multiple locations or services different types of rolling stock, portable jacks offer real advantages. They’re designed to adapt to the job, not the other way around.

Whether you’re working in a small facility, a satellite depot, or a space with limited infrastructure, portable jacks bring the lift to where it’s needed most.

Railquip’s portable systems come with all the safety and diagnostic features you’d expect from a top-tier product, without the complexity of a fixed install.

Why they work:

- Easily moved between tracks or facilities

- Expandable and serviceable, with competitive spare parts availability

- Can be operated independently or centrally via the control console

- Emergency stop buttons and height displays are standard on every unit

You get full lifting power and reliability, with the bonus of mobility and setup flexibility.

4. When fixed systems make more sense: strength, scale, and integrated safety

Fixed jacks shine in environments where lifting is a frequent, predictable part of your workflow. If your facility performs scheduled inspections, overhauls, or large-scale servicing, a fixed system offers the stability and integration needed to maximise throughput and minimise downtime.

Railquip’s fixed solutions are customisable and often integrated with hoists, drop tables, or body support stands making them ideal for large transit authorities or freight carriers.

They excel in:

- Heavy-duty lifting of railcars or bogies with minimal manual setup

- Full workshop integration with multiple access points and support equipment

- Precise alignment and built-in emergency stop, high/low limit switches, and load balancing

- Projects where repeatability and capacity are critical over time

These systems are about scale, control, and long-term investment with Railquip offering tailored installs based on your facility layout and fleet requirements.

5. How to decide: matching your project scope to the right equipment

Still not sure which route is right for you? The decision often comes down to how you work, not just what you’re lifting.

Are you working across multiple sites or focused on a single workshop? Do your teams need mobility, or is precision and throughput the priority?

Answering these questions will help you match your lifting needs to the right system and avoid over- or under-investing in equipment.

Here’s what to consider:

- Mobility: Will your jacks need to travel across locations or stay put?

- Available space: Do you have a permanent pit or shared use area?

- Work volume: How often are you lifting — daily, weekly, monthly?

- Maintenance timelines: Are you planning short-term service or long-term overhauls?

Railquip’s team will work with you to evaluate these factors and recommend either a portable setup, a fixed installation, or even a hybrid solution that adapts to both.

Conclusion

Both portable and fixed railroad lifting jacks bring valuable capabilities to rail maintenance, but the right choice depends on your operational context. Portable systems offer flexibility and fast deployment, while fixed solutions deliver stability and integrated safety for long-term operations.

At Railquip, we engineer for both. Whether you need a compact portable set for light rail or a full fixed hoist system for a major depot, our team can guide you to the most effective and future-ready solution.

So if you’re ready to upgrade your lifting system?

Contact our team at Railquip to discuss your project and discover the best railroad jack solution for your needs!