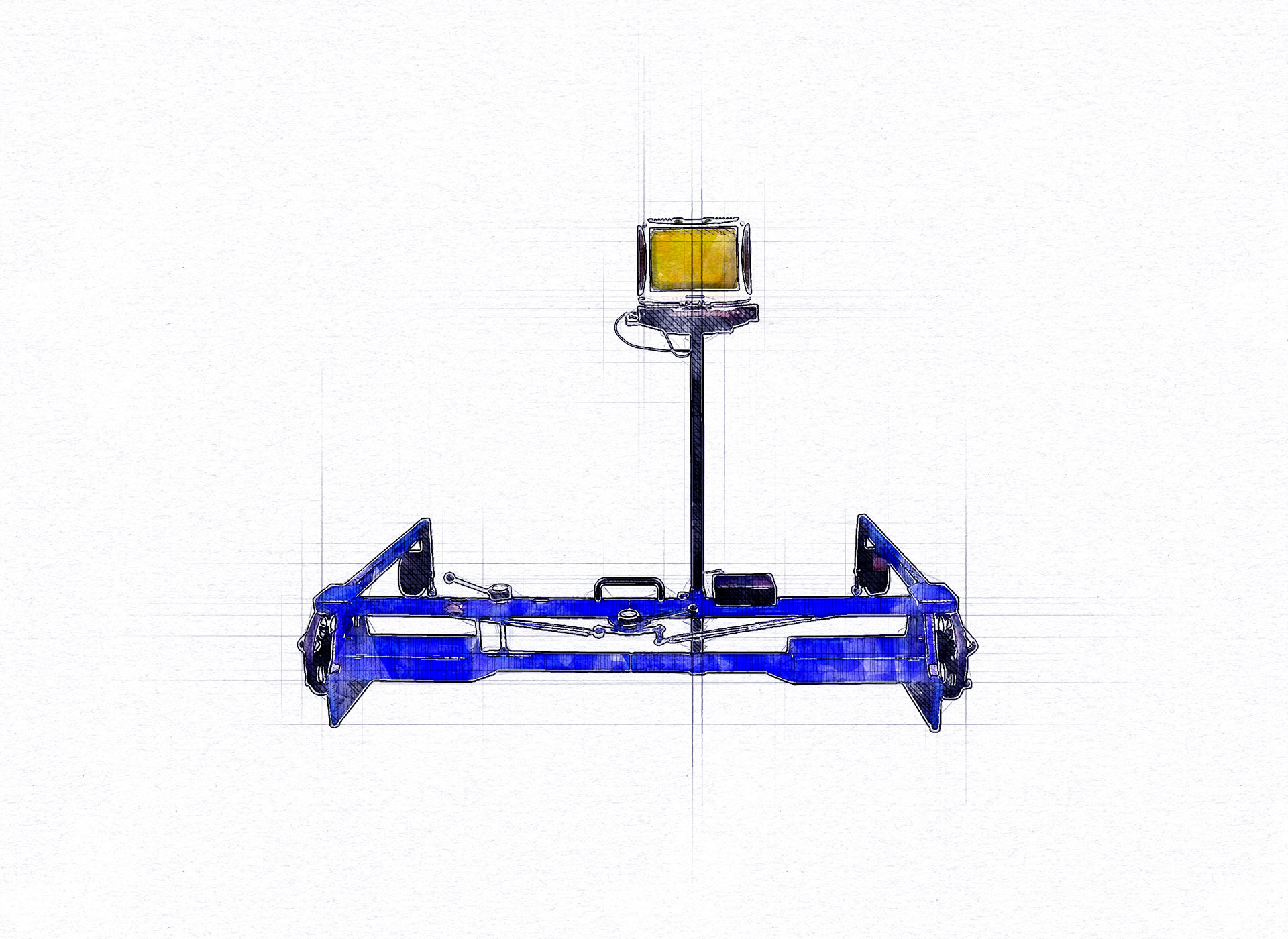

Truck Test & Assembly Stands

SE011

Key Specifications

- The gear supports are hydraulically adjustable in height

- The motors will be mounted with the aid of a ½ ton-capacity chain hoist

- The pressure test beam will be operated hydraulically

OVERVIEW

The gear supports are hydraulically adjustable in height.

The motors will be mounted with the aid of a ½ ton capacity chain hoist.

Pressure test beam will be operated hydraulically.

Contact us for more information

Contact us for more information