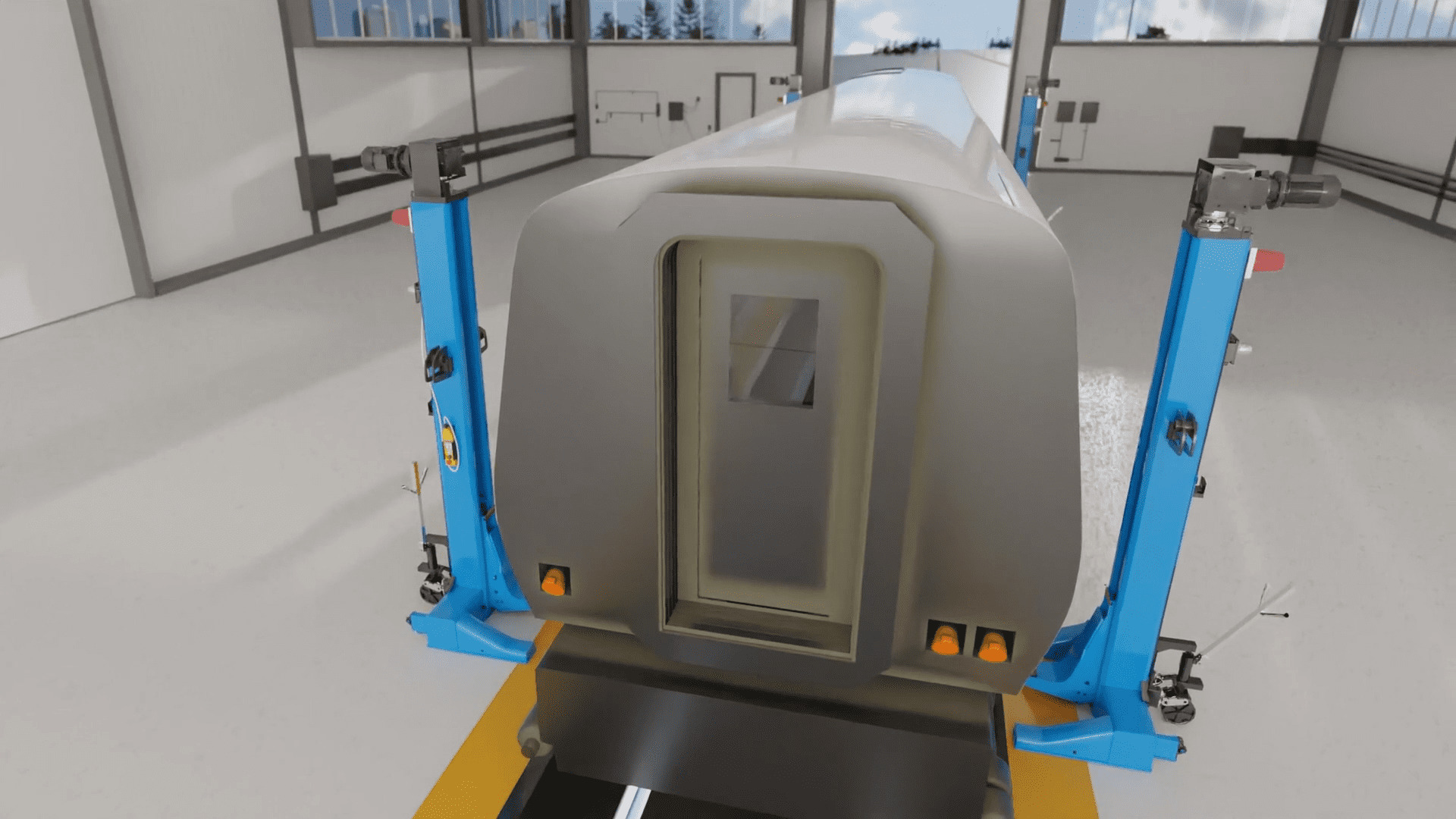

Portable Electric Jacks

LE001

Key Specifications

- Highest standards of lifting safety

- Lifting capacity of 5 -60 tons per column

- Lifting sets can be controlled from a single column or a central console

OVERVIEW

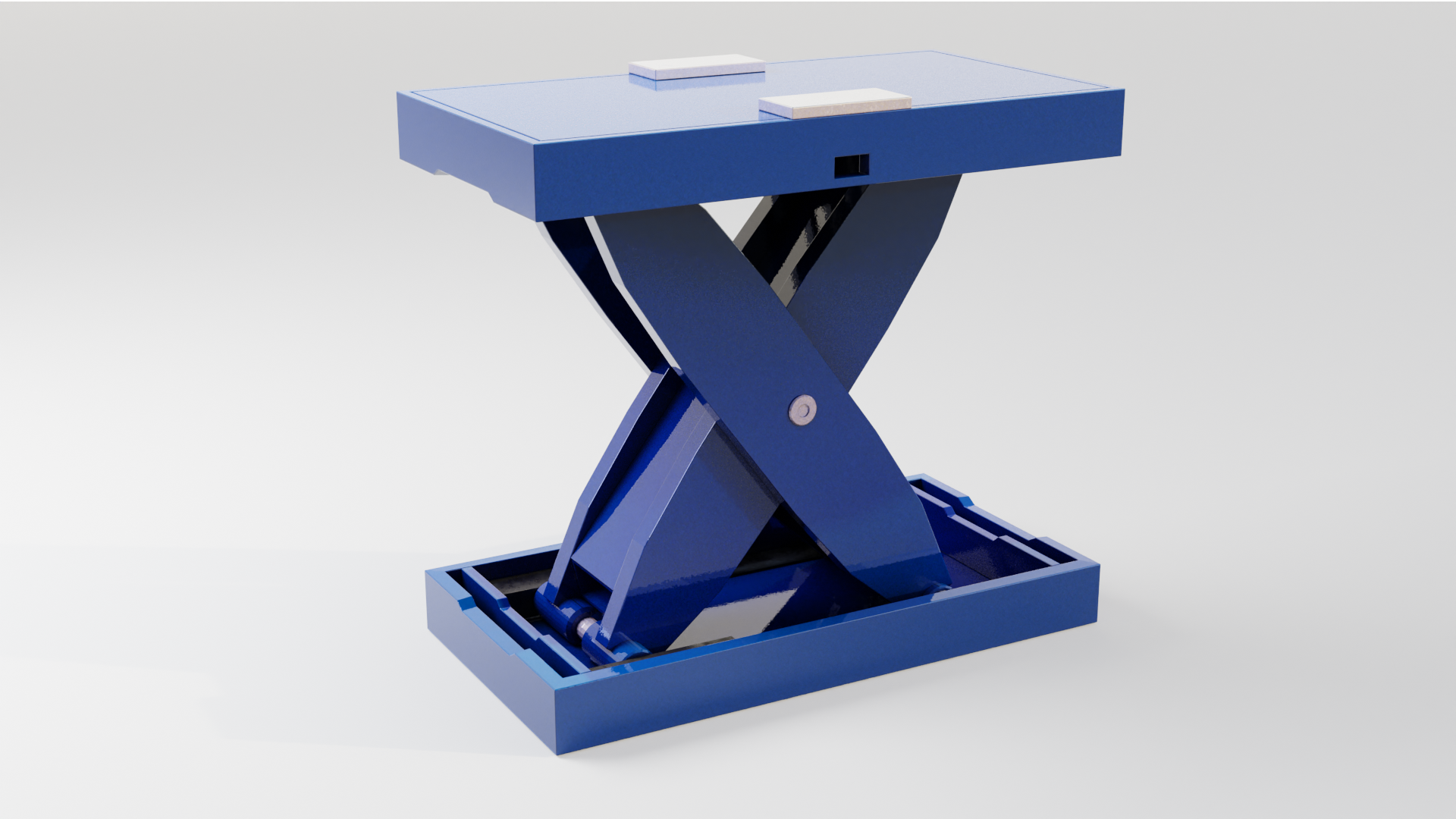

Self-locking, non reversing lifting spindle nut with safety follower nut.

Enclosed gearbox with brake motor with long life lubrication.

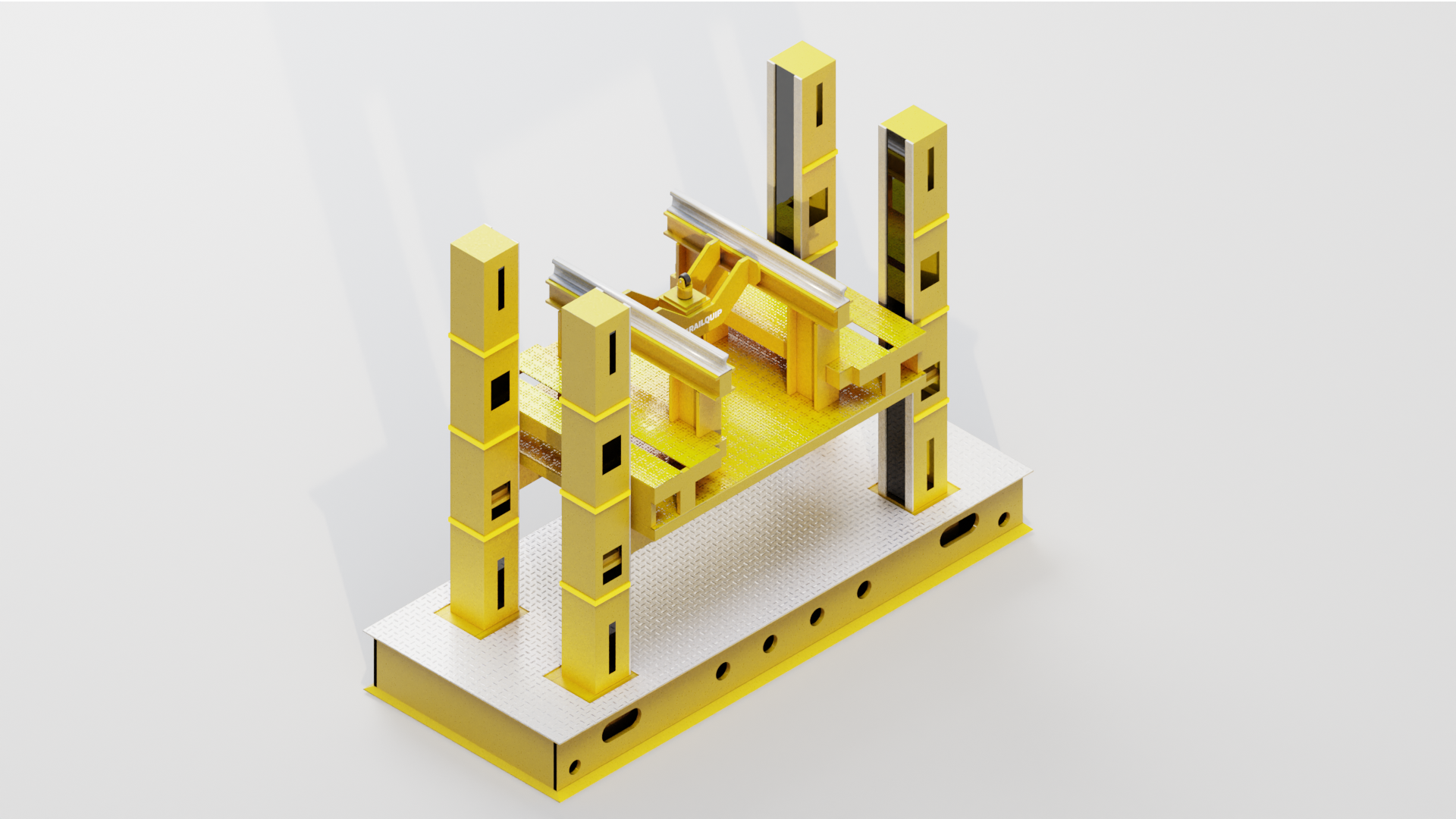

Customized lifting accessories.

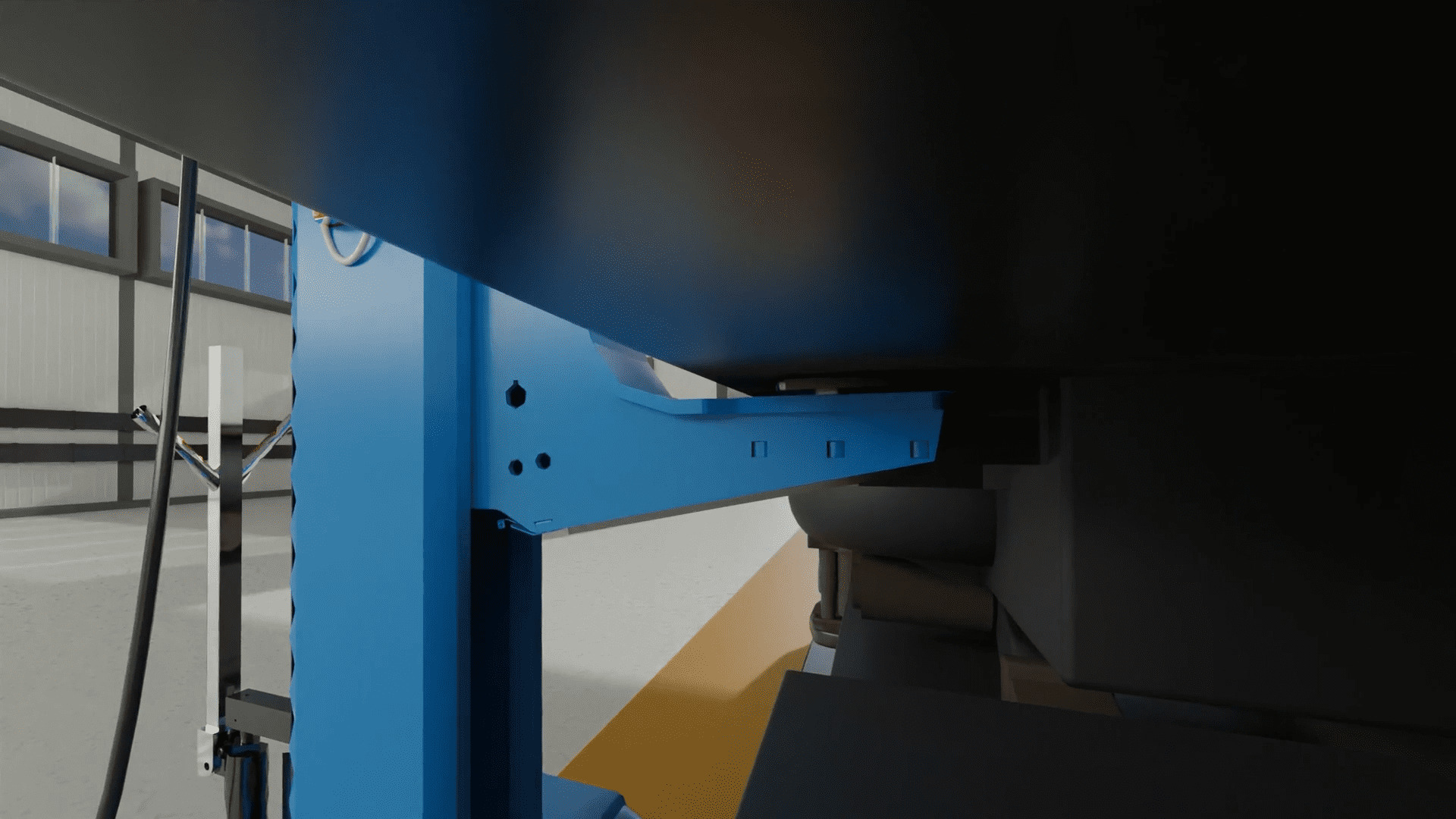

- Low position of the lifting cantilever above the top of the rail.

- Lift columns are of Heavy Duty all-steel construction with built-in roller guides.

- The self-locking lifting spindle is suspended from the upper head by a self-aligning roller

- The gear motor contains roller bearings sealed in an oil bath, flanged to the brake motor.

- The spindle nut is made of cast bronze.

- The lifting carriage is guided within the lift column by means of wheel-flanged rollers.

- The cantilever can be designed to be horizontally adjustable by means of a manually operated gear.

- Columns can be designed to be moved by hand on the concrete floor, on an embedded auxiliary rail, or electrically on an auxiliary rail.

- The lifting columns are lifted and lowered on their traveling wheels by means of a hand crank.

- Lifting sets can be designed to be controlled from a single column, hand-held remote control pendant, central console, or any combination of the three.

- Customized lifting accessories, cross beams, claws, or other suspensions can be offered for differing situations.

- Rolling Jack Support Stands in various capacities are available.