The well-being of your workers must always be a priority!

Did you know that during the year 2021 private industries reported over 2.6 million nonfatal injuries and illnesses in the workplace? That same year The Bureau of Labor Statistics announced more than 5,190 fatal injuries, one of the highest annual rates since 2016. As numbers keep growing the importance of safety measures becomes clearer.

Safety measures are meant to protect you and those around you. Clear guidelines will not only boost the efficiency of your staff but will also keep them safe during shifts. The actions you take toward a safe operation will allow your workers to get to their homes and families safe and sound every night.

At Railquip, one of our core values is the safety of our workers and users. That is why we invite you to take care of yourself, especially in places like rails and workshops, as they represent a higher risk of accidents due to the handling of machinery and other tools. Remember! It’s your responsibility to create a safe environment.

Guidelines that ensure a safe workspace:

- Provide training to the operators: Personnel training is essential for safety. Heavy machinery is often involved in fatal injuries as hazards are not correctly assessed and personnel lack proper training. Continuous training must be provided, not only when a new product is purchased.

- Equipment maintenance: Companies need to establish channels for the continuous inspection and maintenance of machinery. The equipment must be subject to periodic controls, not only when damage occurs. This will help prevent accidents related to electrical damage or similar.

- Safety regulations: Well-implemented safety regulations will keep your staff safe when using equipment or working in the shop. Proper training should be done periodically and whenever necessary. Staff can prevent accidents if they know how to identify and assess hazards, which will lead to a decrease in injuries.

Benefits of a safe operation.

- Improved health, safety, and wellness: When a company prioritizes safety it ensures a positive environment in the workplace. The efficiency and correct development of the activities will depend on the well-being of the operators.

- Fewer accidents and injuries: Decreasing accident rates depends on the correct implementation of safety guidelines. Following safety protocols will automatically imply fewer accidents and injuries.

- Improved productivity: Having workers on medical leave will negatively impact the company’s productivity. Preventing accidents will keep everyone in good health while performing work activities, resulting in less downtime.

- Saving costs: Accidents imply higher insurance costs, payment of medical leaves, higher downtimes, and other negative effects that affect productivity. Investing in safety training upfront will reduce costs resulting from injuries and accidents.

How do Railquip and its equipment provide safe workspaces?

At Railquip we believe in the importance of providing adequate training to the personnel as well as constant maintenance for the equipment.

We offer you:

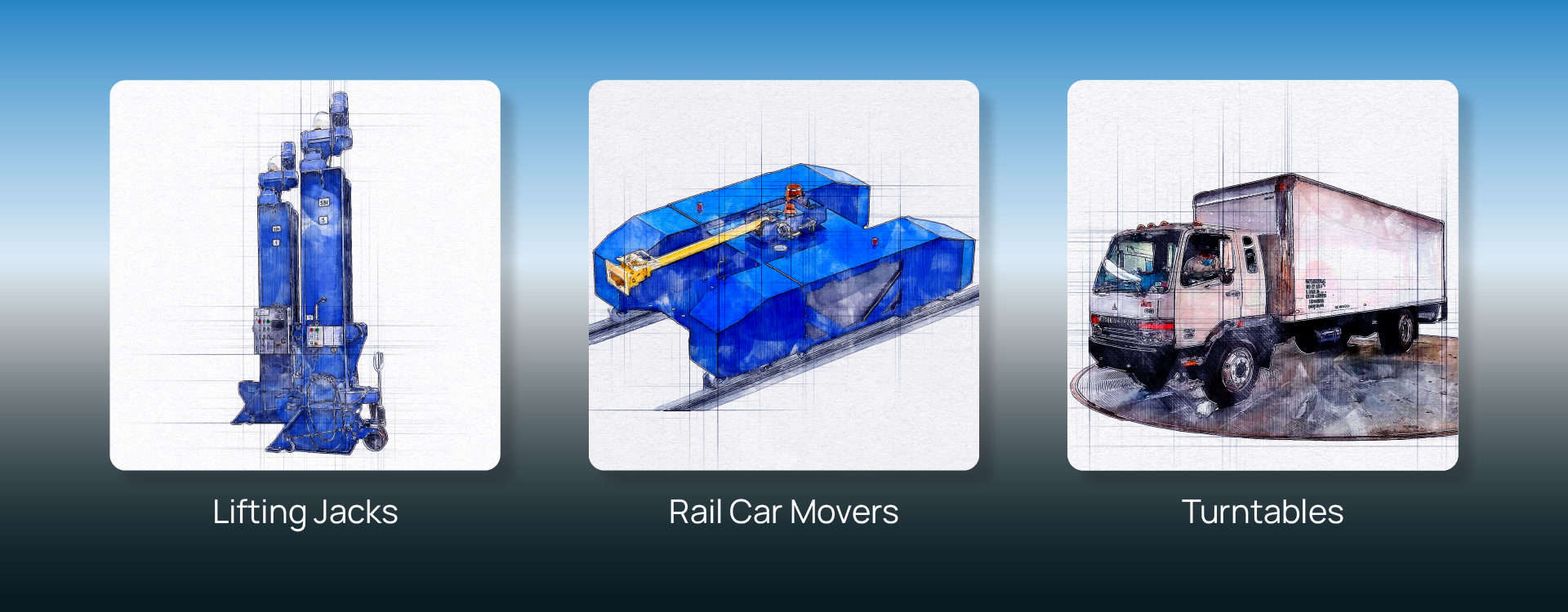

- Training: At the time of purchase, a professional from our company will be in charge of training the staff who will handle the equipment. The training consists of theoretical and practical classes, which culminate in the certification for the use of the equipment. If you are interested in acquiring and training your personnel with one of the most efficient and safest systems for railcar movers and lifting jacks, click here and contact us.

- High-quality equipment: Using the right machinery in the right way will reduce accidents inside and outside the workshop. We provide the finest materials and technologies to ensure your products are effective and long-lasting.

Among our catalog, you´ll find one of the safest systems for turntables and rerailing equipment.

These ensure high precision, a low error rate, and the possibility of remote control, creating safe distances between the machinery and the rest of the staff. To see the full range of available products click here.

Maintenance services: Our team provides continuous maintenance for the company’s machinery and other brands. We make sure every piece of equipment is in good condition, helping to reduce potential hazards. If you are interested in regular maintenance of your equipment, click here and get in touch with our team of experts.

The safety of your workers should always be a top priority. If you are interested in more information about our products and services, don’t hesitate to contact us.

Source: